Introduction

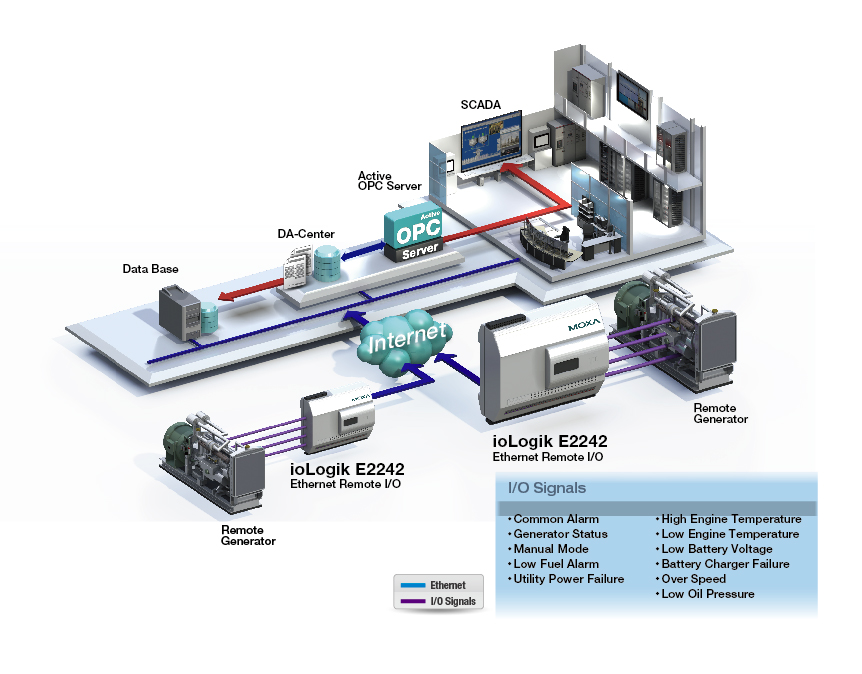

Before deploying a new automatic data acquisition system, a technician from this generator leasing company was required to remain onsite to manually record the status of the company’s generators. The information was entered into the company’s central database by another engineer working in the main office. Only then could the data be accessed from a web browser HMI by maintenance engineers and end-users. With the real-time online data logging suite that goes with Moxa’s smart I/Os, no programming is needed, and only a few steps are required to configure the software. Moxa’s DA-Center™ software will automatically convert I/O data from the generators into database format. Since the software is free, the total cost of ownership of Moxa’s system is much lower than traditional SCADA historical or custom logging software.

System Requirements

- Cut software and engineering costs and increase operational efficiency

- Simplifies the conversion of historical data into Excel or Access spreadsheet

Moxa Solution

Moxa DA-Center is an online data logging tool that works with Moxa’s smart remote I/O solutions. With DA-Center, you can cut software and engineering costs and increase operational efficiency by automating your remote asset management system. Moxa DA-Center makes real-time data collection easier, and simplifies the conversion of historical data into a database-ready format. DA-Center’s standard OPC interface interacts directly with Moxa Active OPC Server to build a bridge between field data and databases or spreadsheets.

Why Moxa

- Cost effective compared with traditional SCADA historical or custom logging software

- Real-time and ready-to-run—no programming required

- Event time stamping for generator set’s (genset) health status history tracking