Today’s companies need to evolve how they interact with, react to, and provide services for their customers if they hope to gain new revenue and value-producing opportunities. Digitalization is a key enabler for industrial applications, and unlocks improvements for two different innovation models:

- Operation Model Innovation: Increasing operational efficiency and productivity by minimizing machine/asset downtime, improving asset utilization rates, etc. One example is utilizing real-time machine monitoring to better understand machine capabilities to enable improvements in production efficiency and maintenance scheduling.

- Business Model Innovation: Enhancing competitive advantages and value creation through a fundamental change in how a company delivers value to its customers. For example, some OEM machine manufacturers transformed their business by moving from onetime sales of machines to a machine-as-a-service business model that brings recurring revenue streams over a machine’s lifetime.

No matter which strategy your business chooses, IT/OT convergence is critical to realizing its success. By merging IT and OT systems, businesses can take full advantage of their scattered but valuable data to maximize their technological capabilities and transform their business.

Digitalization brings increased network complexity, so creating one unified network is important to increase efficiency and system reliability while simplifying maintenance. Achieving one single unified network requires two things. Namely, using new technologies such as TSN to consolidate various industrial Ethernet protocols used by different kinds of devices and equipment, and preparing for future network needs and opportunities. This transformation requires time and resources, but businesses still have immediate needs that must be fulfilled. Therefore, we recommend businesses take a step-by-step approach on their digitalization journey and focus on incremental improvements that are also ready for future needs.

In this article, we aim to give practical advice on how to streamline industrial communication networks while futureproofing your investments so you can be ready to harness the benefits of tomorrow.

Be Prepared for the Future Networking Needs of Your Business

-

To Support Increased Data Connectivity, Streamlined Edge-to-core Solutions Are Required

The rapid growth of IT/OT converged applications is introducing countless numbers of sensors and machines into industrial networks, resulting in more and more data that needs to be transmitted and exchanged. One example is with the emerging application of AI with machine vision, which can be used to improve quality inspection, detection for worker safety, or facility security. This has resulted in IP cameras being adopted on a massive scale in industrial applications. High-resolution cameras can improve performance and accuracy, but also have larger file sizes and video streams that require more bandwidth and increased network performance. This, like many IT/OT converged applications, requires an increasing number of networking devices, but they can be difficult to install in already crowded control cabinets. Additional engineering efforts are also required, putting a significant burden on field engineers. This makes network solutions that can be easily integrated more and more important.

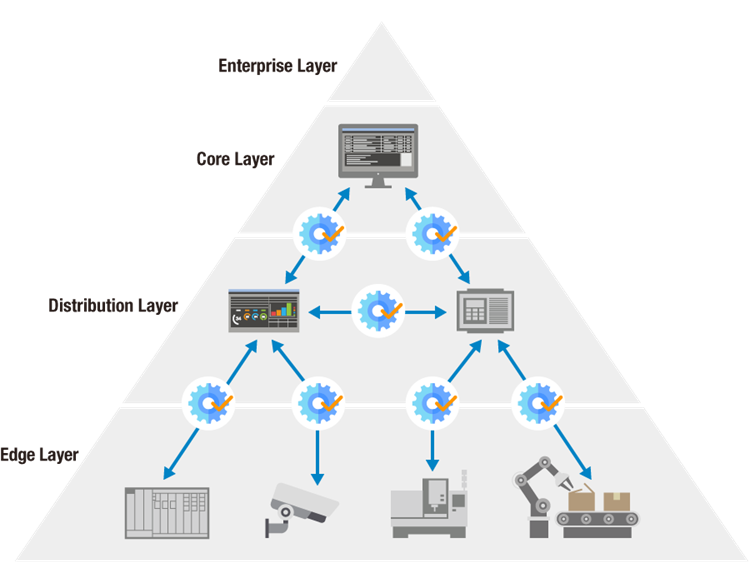

Under such circumstances, ensuring smooth communication for converged networks requires businesses to foresee their future operational requirements and incorporate the flexibility needed to prepare for them. Therefore, we recommend you select solutions with a compact size that fits into control cabinets more easily, and a modular form factor that allows you to add connectivity and capabilities as your needs grow. Making sure you have support for multiple industrial protocols at the edge layer lets you easily enable interoperability and integration with SCADA/HMI systems, providing enhanced operational performance and flexibility. Bandwidth and performance at the distribution and core layer are also important for streamlining edge-to-core data connectivity. Moxa provides a reliable network foundation that enables seamless data transmission and easy integration so you can create futureproof networks that are reliable from the edge to the core.

-

To Face the Growing Risks to Network Security, Layered Protection Is Critical

The convergence of IT and OT networks is happening at the same time as rapid adoption of IIoT technology across both networks. However, this means there is now an increased overall attack surface, as well as additional attack vectors. Cybersecurity risks are exponentially rising, and there are increasing numbers of reports about disrupted operations in industrial control systems (ICS) and mission-critical infrastructures—such as power generation plants—due to a lack of sufficient OT network security that led to unauthorized changes or configurations. Historically, OT devices were physically separated from other networks through air-gapping. But today, IT/OT convergence is dissolving the air gap between ICS and the Internet, exposing OT infrastructure to potential cyberthreats. Administrators now face the challenge of managing existing vulnerabilities hidden inside once-isolated OT networks, but with the added complexity of IT-based threats. However, ensuring your OT network’s security is not the only criteria for a successful industrial application. Ramping up network security is important, but doing so while ensuring your industrial operations can maintain reliable, uninterrupted operation is a must.

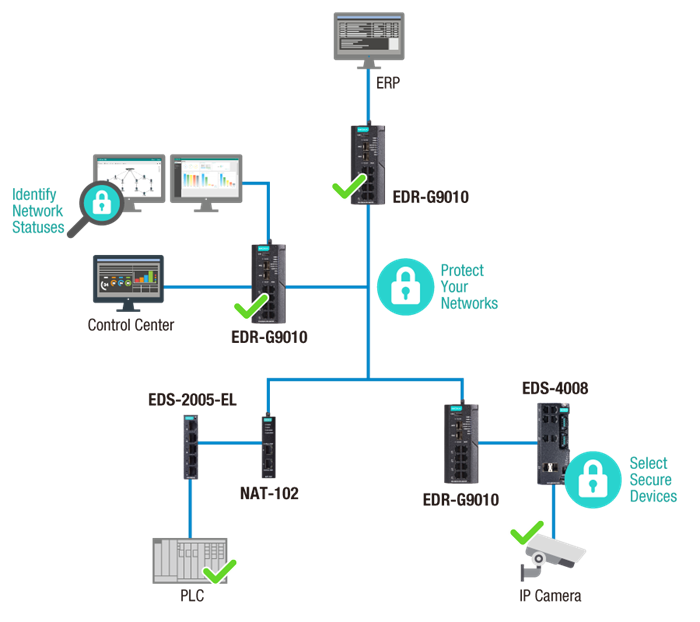

To enhance industrial network security while creating a robust network foundation, the core principle is to focus on secure networking with defense-in-depth protection. To begin with, you need to select security-hardened devices that comply with industrial security standards, such as IEC 62443 and NERC CIP. With these building blocks, you will still need to build another layer of protection to guard your network from attacks through practices such as essential network segmentation and proactive threat prevention. Finally, visibility to monitor the security status of the network is a must to help you detect and respond to cyberthreats in a timely manner. Moxa has holistic network security that is designed for the specific needs of industrial networks by offering three layers of defense-in-depth protection, helping businesses ensure both network protection and availability when transitioning to a converged infrastructure.

-

To Handle Growing Networks, Simplifying Network Management Is a Necessity

When IT and OT networks converge, network complexity increases, making it more and more important to have proper network management in place to ensure the network runs smoothly, efficiently, and continuously. A single point of failure could significantly affect the entire OT infrastructure and even IT networking systems, which could cause costly downtime. Service providers need a network management tool that gives them a clear view of the network status at customer sites, shortens troubleshooting times, and enables remote maintenance.

Optimally, an OT network management tool should have these capabilities:

- Network Visibility: This is by far the most important, but also the most fundamental element. Other helpful features would be monitoring of performance, traffic load, and security status of network devices.

- Quick Diagnostics: This is the ability to detect downtime and pinpoint the root cause of issues so you can minimize impacts to the business. Notifications for customized events can enable businesses to resolve issues in a timely manner, sometimes before incidents even occur.

- Easy Maintenance: This includes the ability to remotely back up or restore device configurations and upgrade firmware for devices across a deployment, all from a centralized location. This allows administrators to perform upgrades and fixes without sending out engineers to maintain devices individually on-site, which can be even more difficult if devices are installed in control cabinets or inside machines.

Good network management tools enable you to improve network performance and availability, detect problems and react to them quickly, and make future expansions easier to implement. Moxa offers OT-centric network management solutions that are easy to use and created to address the needs of OT engineers, reducing the efforts needed to tackle the issues that come with increasing network complexity, and can even empower companies to provide improved aftermarket services and even new business models such as machine-as-a-service.

Leverage Futureproof Network Infrastructure to Ensure the Success of Your Digitalization Journey

As you work to merge your IT and OT networks on the path to digitalization, your network infrastructure needs to evolve to meet the new demands that will inevitably emerge. As trusted experts in industrial networking, Moxa is committed to helping businesses take the leap into the next generation of industrial networking by addressing the needs of their various applications and helping them successfully create futureproof industrial network infrastructure that helps them accomplish their innovation goals.

To learn more about how you can implement our futureproof network infrastructure in different applications, take a look at these application notes: