The following three success stories illustrate how Moxa has assisted oilfield service companies to overcome their challenges and achieve higher efficiency while lowering the total cost of ownership.

Case 1: Smart Data Acquisition for Natural Gas Wellhead Monitoring

In order to enhance efficiency, one of the largest energy companies in Southeast Europe has introduced a wellhead automation monitoring system for its natural gas production. The company started by deploying cellular communications between gas fields and a control center to reduce the upfront infrastructure cost. This was achieved by deploying Moxa’s ioLogik 2542-GPRS smart remote I/O, which is a 4-in-1 data acquisition solution. The primary reason why they chose Moxa’s solution was because it did not require additional cellular routers or switches to be installed in the small cabinets that were already being used. In addition, the smart remote I/O is powered by solar panels, which allowed the total cost of ownership to be lowered even further. The smart remote I/O and Moxa’s MX-AOPC UA server work together to intelligently manage data logs by scheduling active messages to be automatically pushed from the ioLogik 2542-GPRS to the SCADA systems at the control center. This smart data acquisition takes place when the I/O state changes or preconfigured events occur, allowing information to be accurately and efficiently pushed to the SCADA system as it becomes available.

Featured Product:

ioLogik 2542-GPRS Series

Smart cellular remote I/O with Click&Go Plus

• A 4-in-1 data acquisition solution: Smart I/O, Modbus Gateway, Unmanaged Switch, and Data Logger

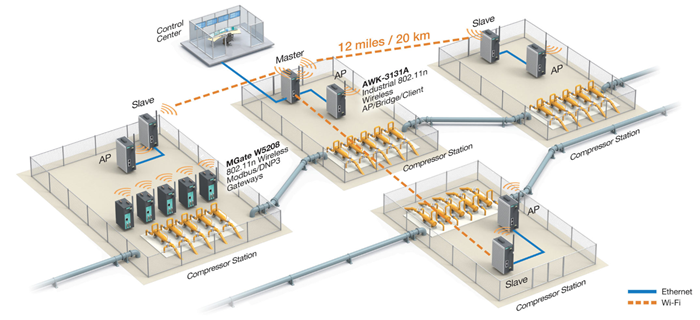

Case 2: Long-Distance Wireless Communications for Natural Gas Pipeline Monitoring

One of the largest energy companies in the U.S. operates midstream services across several counties in the Eastern states. In order for the company to migrate towards a complete digital oilfield, the company retrofitted the backhaul portion of their network for pipeline monitoring. They chose to deploy Moxa’s AWK-3131A wireless AP because it can operate on the 5 GHz band, which experiences less interference than the 2.4 GHz band. Traditionally, it has been very difficult to achieve smooth transmissions across distances of up to 20 km using the 5 GHz band. The AWK-3131A Series uses Moxa's proprietary technology to provide stable communication over long distances, helping the energy company build a reliable wireless backhaul for their network. This allowed the compressor stations and the network operation center to communicate smoothly over longer distances.

For field site aggregation, the company deployed Moxa’s MGate W5208 wireless protocol gateways to retrieve Modbus data from the field sites and send it to the compressor stations over a wireless connection. As the company previously used wireless communications for data aggregation, deploying Moxa’s MGate W5208 wireless protocol gateways avoided incurring the additional cost of building a wired communications network.

Featured Products:

AWK-3131A Series

Industrial 802.11n Wireless AP/Bridge/Client

• Supports the 5 GHz DFS channel for reliable and secure wireless communications across distances of up to 20 km

MGate W5208 Series

Industrial 802.11n Wireless Modbus/DNP3 Gateways

• Retrieves Modbus/DNP3 serial data through an 802.11 network

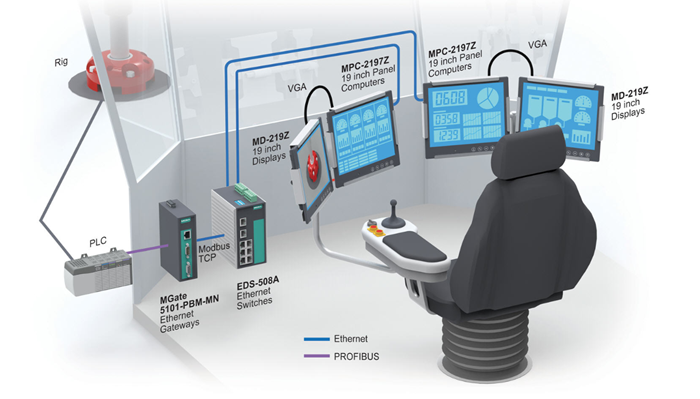

Case 3: Building a Modern Drilling Chair to Help Lower the Total Cost of Ownership

An oil & gas system integrator that specializes in drilling solutions and operates globally was tasked with deploying a modern drilling chair solution. The reason the previous solution had to be updated was because it suffered severe interference due to transmissions from the oil rig being sent to the control room via VGA cables. The system integrator removed the two existing PCs at the oil rig and installed two of Moxa’s MPC-2197Z touch panel computers on the drilling chair. The two displays that were originally in the control room were replaced with Moxa’s MD-219Z displays. As all of the equipment is now located on the drilling chair, there is minimal interference and it is much easier for the operator to perform drilling. The second challenge that had to be overcome before the customer could seamlessly migrate to the new drilling chair was protocol conversion. Moxa’s MGate 5101 Ethernet gateways played a key role in simplifying this transition as the most commonly used PLC protocol at oil & gas field sites is PROFINET, which is unable to directly connect to panel computers. In addition, Moxa’s EDS-508A Ethernet switches were deployed to transmit data smoothly into the control system.

After an integrated, networked system had been implemented, the operational efficiency of the drilling chair was successfully enhanced in a cost-effective manner.

Featured Products:

MPC-2197Z Series

19-inch Fanless Panel Computers

• Features an Intel 3rd generation processor

• Fast, sensitive, multi-touch capabilities

MD-219Z Series

19-inch Displays

• Features innovative and user-friendly controls

EDS-508A Series

Industrial Managed Ethernet Switches

• Supports advanced management and security features, and is suitable for harsh industrial environments

MGate 5101-PBM-MN Series

Industrial PROFIBUS-to-Modbus TCP Gateways

• Automatically scans PROFIBUS devices for easy integration

For more success cases in the oil & gas industry, please download the Oil & Gas Success Case Guidebook here.