In the past, automation systems were relatively closed off and developed a unique set of highly specialized protocols including Modbus, EtherNet/IP, and PROFINET. These protocols are known as industrial fieldbus protocols and provide unique benefits for different system application purposes.

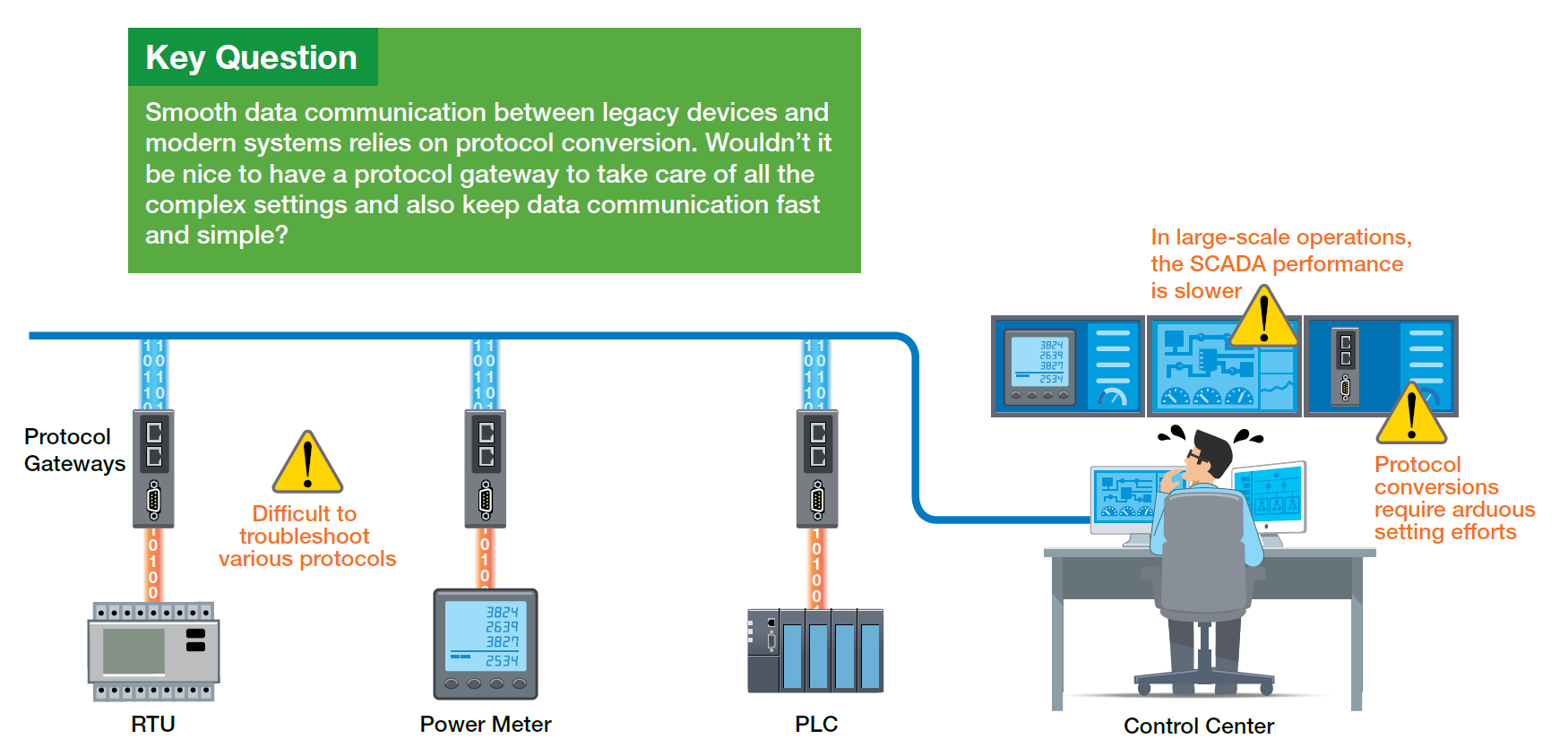

Today, the push towards connected factories has also seen a growing demand for protocol conversion due to two main reasons. First, legacy devices generally use serial-based communication protocols whereas modern SCADA systems, which are becoming increasingly popular in industrial automation, rely on Ethernet communications. To enable smooth data communication between legacy serial devices and SCADA systems, serial-to-Ethernet protocol conversion is necessary. Second, a factory may have several independent control systems. To enable system-to-system communication for enhanced operational efficiency and visibility, you need a way to translate data between systems.

Key Criteria for Choosing Protocol Gateways

Protocol gateways play an important role for smooth data communication in a converged communication system. The following three criteria provide guidelines to help you choose a protocol gateway that offers maximum benefit. However, if your legacy serial devices speak in proprietary protocol instead of industrial fieldbus protocols as we mention above, serial device servers can provide a simple bridge between your legacy serial devices and modern communication systems. Read our article to learn how to choose the right serial device server.

Start Strong With Faster Configuration

If you thought manually configuring IP addresses and COM port settings for serial device servers was painful, just wait until you have to deal with industrial protocol conversion settings. Industrial protocol conversion settings are even more complex and involve many different data formats. Even the most experienced engineer could be overwhelmed. That’s why a good protocol gateway does more than just convert different protocols. Besides simplifying byzantine configurations for both northbound and southbound protocols, the protocol gateway also has to properly map which data from which protocol needs to be converted. A graphical user interface that provides these functions on an intuitive and easy-to-use screen can really help speed up the configuration process. Watch our video and see how easy it can be to complete protocol conversions.

Take the Trouble Out of Troubleshooting

When systems are down, you lose time, productivity, and most importantly, money. Naturally, engineers want to fix problems quickly. But troubleshooting isn't always easy. If multiple devices using different protocols are being connected, pinpointing the cause of a communication problem becomes even harder as you’ll need to determine whether the problem originated on the Ethernet end or the serial end. Time and energy are often misspent trying to track down the root cause of a communication failure. Adding to the frustration is the lack of helpful diagnostics tools to pinpoint the root cause quickly. Identifying the root cause to resume system communication requires an efficient method. Here is an example of how you can timely restore communications to your power meters.

Troubleshooting protocol conversion issues requires a way to analyze the packets traveling through the gateway. However, troubleshooting tools and capabilities are sometimes limited due to security concerns (for example, third-party utilities might not be allowed by your IT policies) or platform constraints (for instance, you cannot install utility tools directly on a PLC). So, a protocol gateway that has a handy utility tool or built-in troubleshooting features to quickly identify connection status, timeout frequency, and invalid response counts can really help. Also, never forget the cost and effort spent on troubleshooting when selecting your gateway solution.

Data Acquisition Performance Matters

Balancing cost and performance can be a major issue when you require protocol conversion in a large-scale application. When dozens or hundreds of devices require protocol conversion and communication within a single SCADA system, how can you ensure system performance meets your expectations? You could use a one-port protocol gateway for each field device to ensure instant data conversion and transmission, but the cost would be high and maintenance effort could overwhelm your daily operations. Alternatively, high-port density protocol gateways can provide a cost-effective solution with efficient installation and easy management, but performance concerns may arise over data handling. As most protocol communications are based on poll-and-response behaviors, handling large amounts of data polls also creates loading on gateways, which negatively affects the performance and response times of the SCADA system.

Design your network carefully with a combination of one-port and high-port density protocol gateways. When you choose a high-port density protocol gateway, check if its data polling mechanism can meet your requirements.

An easy-to-use protocol gateway can tremendously improve your system operation. Check the three key criteria above and choose your solution wisely. For example, consider the Moxa MGate protocol gateways that enable efficient protocol conversion and speed up your system operation with smooth data communication. If you are interested in learning more about industrial connectivity, download our E-book.