Net-Zero Targets Passed SBTi Validation

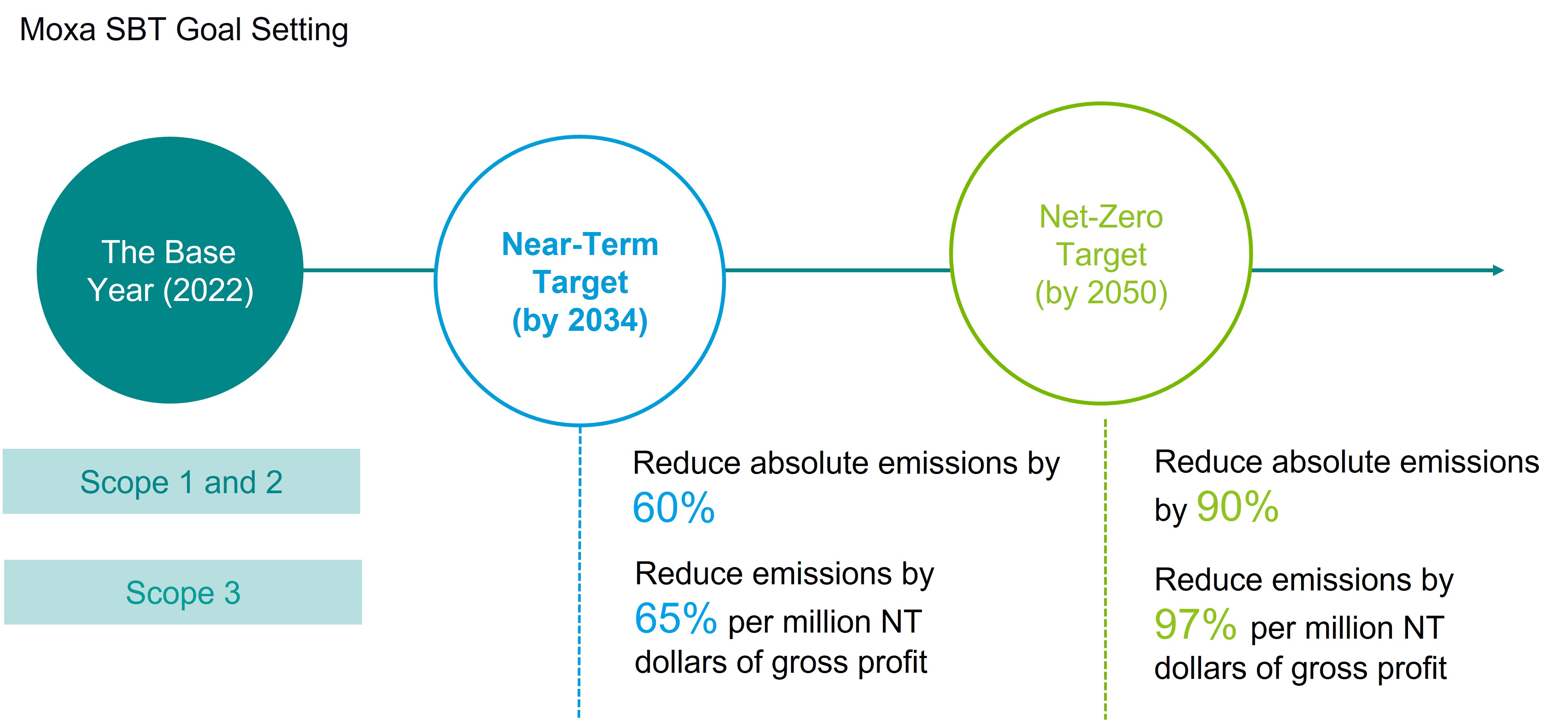

To demonstrate its commitment to net-zero emissions, Moxa pledged to the Science-Based Targets initiative (SBTi) in December 2023. Following SBTi's methodology for setting carbon reduction targets, Moxa completed the process of establishing these targets. Using 2022 as the base year, Moxa set the Science-Based Targets (SBTs) for the near term (2034) and net-zero emissions (2050). The SBTs are in line with the global warming limit of 1.5°C, and officially passed SBTi validation in November 2024. This validation indicates that the carbon reduction targets set by Moxa will help curb global warming to under 1.5°C, aligning Moxa's carbon reduction pathway with international trends, and will jointly attain the goal of net-zero emissions by 2050 with the global community.

Moxa Net-Zero Strategies and Actions

To achieve the goal of net-zero emissions by 2050, Moxa identified three major sources of emissions based on the results of Greenhouse Gas (GHG) inventories assessment, including " purchased goods and services," "use of sold products," and "electricity consumption." Moxa has proposed three key strategies to move towards net-zero emissions. Moxa is committed to gradually achieving the goal of net-zero emissions by 2050 through the following three key strategies: "Low-Carbon Operation," "Low-carbon Product Design," and "Low-Carbon Value Chain."

Strategy 1: Low-carbon Operations

Electricity consumption is the main source of carbon emissions in Moxa’s operations. Moxa worked with a third-party professional team in 2024 to monitor and diagnose energy use behaviors in its plant and offices (including equipment and processes). Through optimized management, Moxa adjusts and improves the operation of high energy consumption and low-energy efficiency equipment on a regular basis to boost energy efficiency and replace old equipment. Moxa implemented a total of 7 energy-saving measures in 2024, saving 91,777 kWh of energy and reducing carbon emissions by 45.3 tons CO2e in total. In addition, Moxa's production plant was set to incorporate high-efficiency energy-saving facilities during the design and planning phase, and also obtained the Gold-level certification of the Green Building Label. All of which provide Moxa with a good foundation for low-carbon operations. Moxa will evaluate the demand for renewable energy and implementation schedule in the future to improve the overall sustainable performance of operations.

Strategy 2: Low-carbon Product Design

The development of low-carbon products is key for Moxa to help customers reduce carbon emissions and enhance market competitiveness. All new-generation products adopt a modular design, which not only increases the flexibility and maintainability of products, but also reduces production costs, increases production efficiency, and extends product service life, thereby promoting the effective use of resources. In addition, Moxa established the Green Design Assessment Method in 2024. The assessment method allows the design team to clearly learn about the carbon emission performance of each design plan and related environmental parameters at the product design stage. Specific improvement plans can then be formulated to help optimize carbon emission reduction in the design stage. In terms of product energy efficiency, Moxa completed the formulation of product power efficiency specifications in 2024, incorporating high performance and low-energy consumption designs into product development processes. Moxa also plans to incorporate the specifications into product design and development processes in 2025. In terms of sustainable product packaging, Moxa began formulating the Green Packaging Design Guidelines and Rating Parameters in 2024, and established the Online Database for Packaging Material Selection. This will help Moxa to more efficiently and accurately design packaging that meets the needs of different markets for eco-friendly and sustainable packaging.

Strategy 3: Low-carbon Value Chain

As a leading brand in the global Industrial Internet, Moxa not only proactively implements carbon reduction actions, but is also committed to working with subcontractors and high-carbon emission partners to promote the low-carbon transition of the supply chain. Moxa works to assist supply chain partners in setting carbon reduction goals, and providing guidance to promote their GHG inventory assessment and obtain third-party certification. In 2023, Moxa assisted all subcontractors in completing their GHG inventory assessment and all of them passed the ISO 14064-1 verification conducted by a third party. In 2024, Moxa further expanded its influence to involve high carbon-emitting suppliers. In the future, Moxa will gradually require supply chain partners to set carbon reduction targets and take action to jointly achieve the goal of net-zero emissions by 2050.

| Key Strategies |

2024 Implementation Results |

2025 Implementation Goals |

| Low-Carbon Operation |

Implemented 7 energy-saving measures, mainly energy-saving measures for the air conditioning system, exhaust system, and lighting system, garnering a total energy savings of 91,777 kWh. |

- Adjust the lighting wiring in the office area in conjunction with the Company's hybrid working policy, and plan for centralized office operations.

- Evaluate the demand for renewable energy and implementation schedule.

|

| Low-carbon Product Design |

- Established the Green Design Assessment Method.

- Established the Moxa Power Efficiency Regulations.

- Proposed the Green Packaging Design Guidelines Outline.

- Established an Online Database for Packaging Material Selection.

- Established the Green Packaging Rating Parameters.

|

- Initiate the Power Efficiency Regulation Project.

- Complete the formulation of Green Packaging Design Guidelines.

- Enhance research and design with power efficiency.

- Perform research on product energy-saving functions.

- Adopt energy consumption efficiency targets and data collection process for new products.

- Adopt development process incorporating the linkage of material carbon emissions and design solutions for new products.

|

| Low-Carbon Value Chain |

Planned guidance and training on GHG inventories assessment for high carbon-emitting suppliers. |

Monitor suppliers with high carbon emissions to complete the establishment of GHG inventories assessment and set carbon reduction targets. |