Packaging Optimization: Creating Lasting Partnerships

Building long-term partnerships with customers is important to Moxa. Our goal is to improve product packaging value, reduce operational costs, and strengthen customer connections through packaging volume reduction and bulk shipping implementation. Driven by this goal, our design team performed an analysis in 2023 on packaging structure and its correlation with operational costs. By actively communicating and collaborating with customers, the team highlighted how better design can enhance three key efficiencies: shipping volume usage, product transportation, and warehouse space usage.

We examined how efficiently popular product models use packaging volume. Ensuring quality, the team redesigned, selected, and combined cushioning materials, product boxes, and outer cartons. The outcome was an uptick in shared packaging models, a decrease in storage needs for materials and finished products, reduced production costs for packaging boxes, and savings in storage and transportation expenses. By optimizing packaging, not only resource waste but also space wastage during transportation is reduced. By reducing greenhouse gas emissions from bulk product transportation by 51 to 56%, this solution helps customers save on logistics and storage costs while improving environmental sustainability.

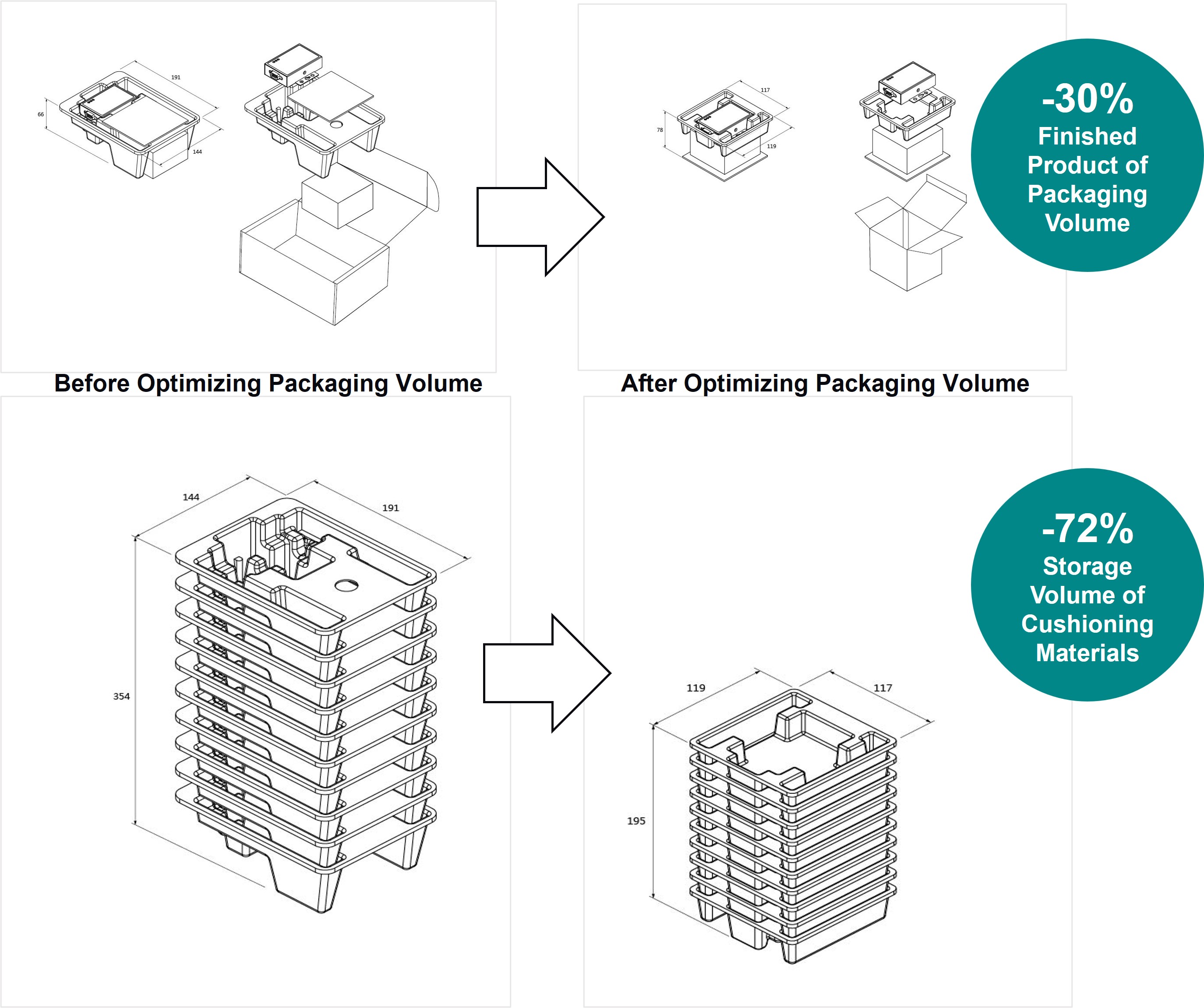

Action 1: Reducing Packaging Volume to Improve Efficiency

After assessing popular product models, it was concluded that 27 models have room for improvement. By redesigning and merging cushioning materials, product boxes, and outer cartons, we decreased the packaging volume of the finished product by 30% and the storage volume of cushioning materials by 72%. Additionally, it enhanced the overall efficiency of product transportation and customer storage space usage.

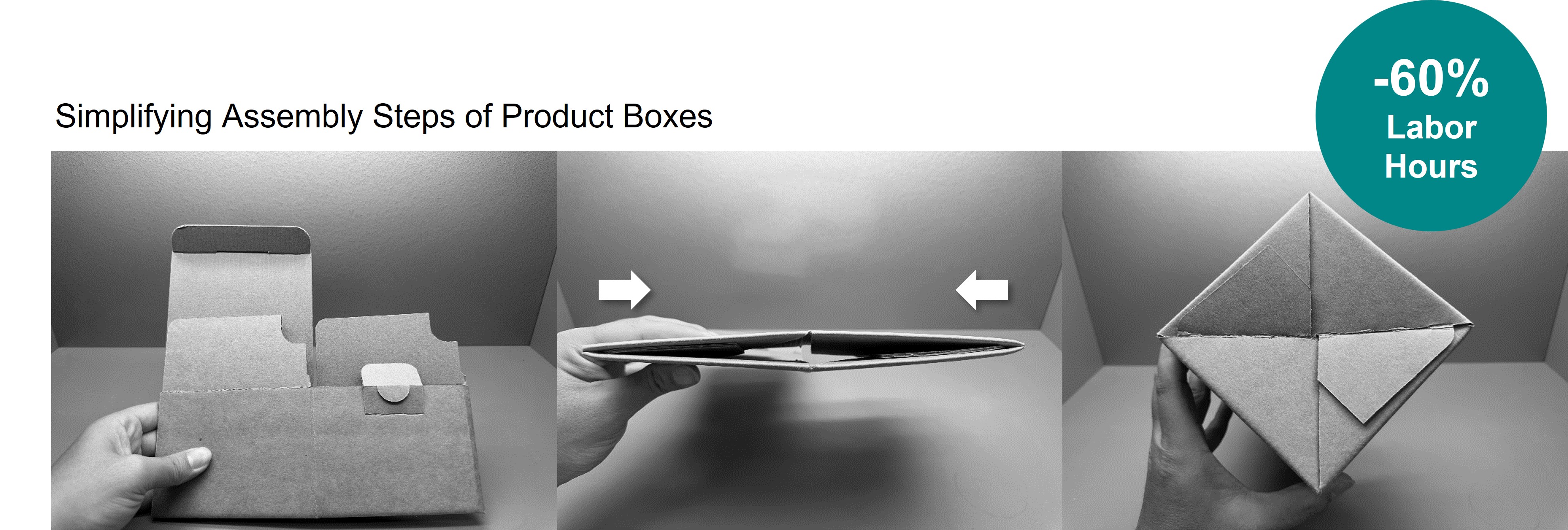

Action 2: Modifying Product Box Design to Reduce Labor Hours

This project decreased assembly labor hours by 60% through redesigning the product boxes and simplifying assembly steps.

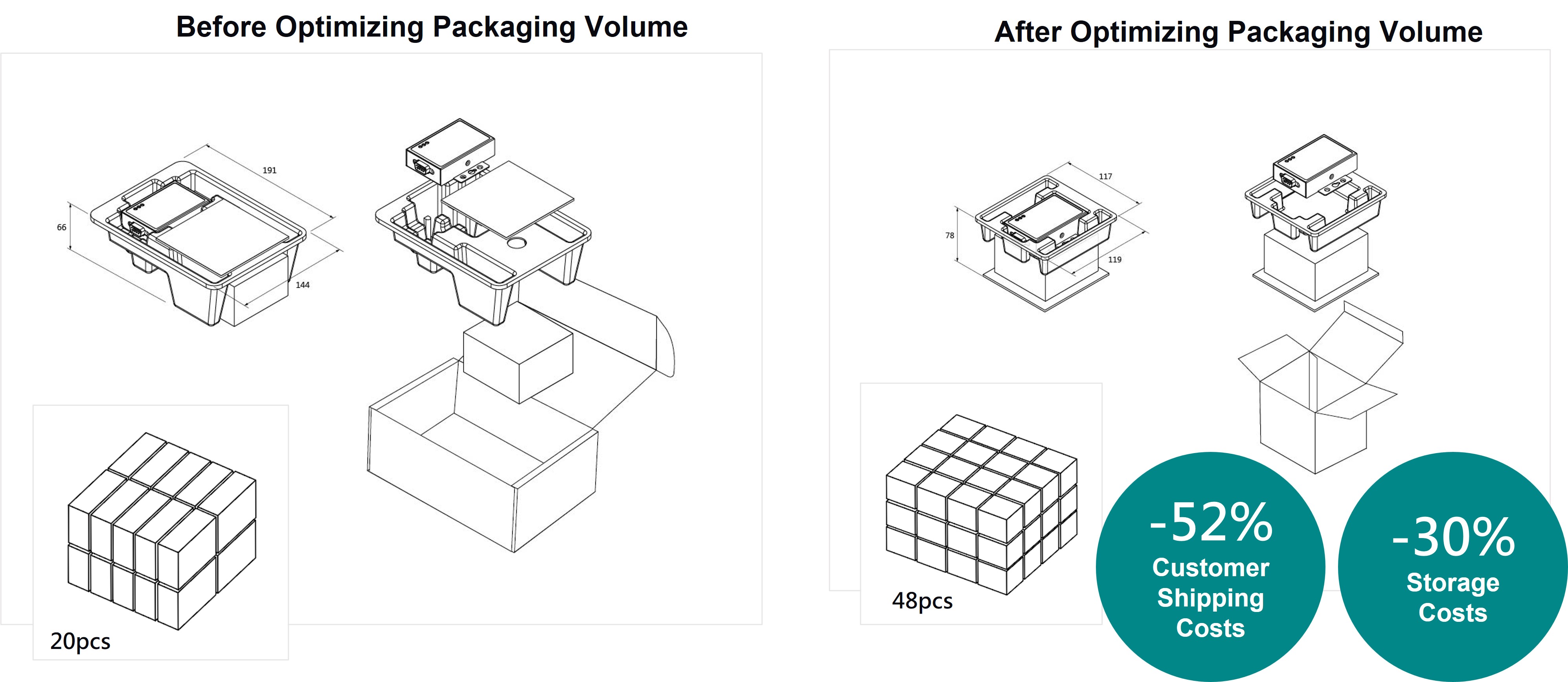

Action 3: Enhancing Logistics Volume Utilization Through Customer Collaboration

By using actions 1 and 2, along with properly sized outer cartons, the volume and weight of product packaging were significantly reduced for the 27 popular products. The products’ logistics volume utilization was enhanced, resulting in a 52% decrease in customer shipping costs and a 30% reduction in storage costs compared to previous bulk sizes. We further collaborated with customers to enhance shipping volume efficiency through adjusting bulk shipping proportions.

Positive Environmental Sustainability: Reducing Logistics Carbon Emissions

Notably, the overall improvement in logistics efficiency led to a 45% reduction in packaging materials usage and decreased logistics loading weight. Besides increasing the bulk volume of product packaging, it also reduced the number of transport trips during the raw material transportation stage. Calculations show that this project can reduce the greenhouse gas emissions of original packaging materials by about 52 to 56%. Additionally, it can lower the greenhouse gas emissions of overall bulk product logistics transportation by about 51 to 56%, making a positive impact on environmental sustainability.