Envisioning efficient and intelligent modern ships, a leading marine engine provider has taken the digitization route to help ship owners enhance their operational efficiency, aiming to reduce fuel consumption and maintenance costs. Digitization in itself requires reliable networking and data analysis. To navigate a route to success, electronically controlled engines are pivotal to help ship owners achieve highly integrated engine control systems.

What Is an Electronically Controlled Engine?

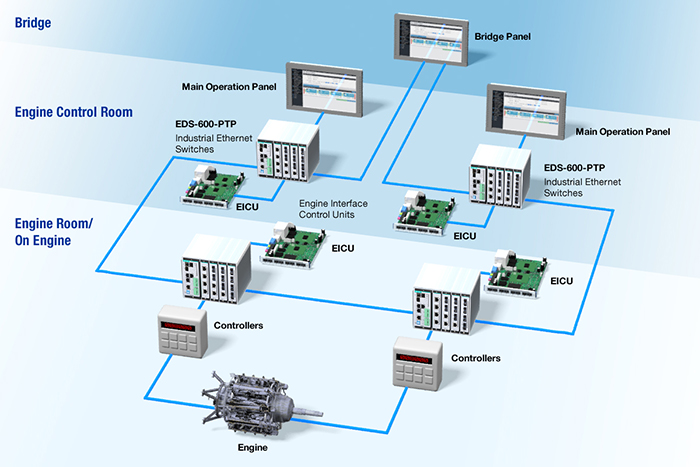

Electronically controlled engines help subsystems connect propellers or engines to the engine room and engine control room, as well as to the bridge or even remote sites. They also integrate controls to start air valves, start and reverse sequences, govern functions, and so on. With highly integrated engine control systems, ship owners can precisely control and increase the visibility of these systems and collaborate better with engine providers. Furthermore, electronically controlled engines provide real-time condition monitoring, intelligent optimization, and facilitated decision-making, enabling both ship operators and engine providers to better leverage onboard systems. Because electronically controlled engines can achieve lower possible propeller speeds, lower fuel consumption, increased flexibility over emissions, easy adjustment, and precise optimization of engine parameters, building them is a crucial step for engine providers to ensure the competitiveness of their engines

Achieving Higher Integration

With electronically controlled engines, the marine engine provider can now build next-generation engine control systems (ECSs) that are highly intelligent. Industrial Ethernet switches are integrated into the ECSs, providing connectivity with high bandwidth, scalability, and reliability to allow integration of various subsystems and applications such as engine controls, cylinder controls, auxiliary controls, condition measuring, and monitoring applications.

In order to provide greater visibility of the whole system, a single converged network is created to connect propellers and engines in the engine room all the way to the control room and the bridge. With this converged network, ship operators can achieve higher integration of the subsystems and can quickly adjust cruising, propulsion, and fuel consumption controls, even in a rapidly changing marine environment. Additionally, when a new controller or a subsystem is added to the system, the controller can be automatically configured through the control network. In order to achieve such a highly integrated implementation, a flexible network design is needed. This is where industrial Ethernet plays an important part by ensuring that networks are flexible, scalable, and future-proof.

During operation, time synchronization plays a significant role in ensuring real-time data communication and precise control across multiple subsystems and applications for various devices such as marine engine controllers. IEEE 1588v2 Precision Time Protocol (PTP) is used to do time-triggered data sampling for the whole engine control system and QoS helps manage data with higher priority. Another key to ensuring seamless operations is to build fast recovery networks with advanced redundancy technologies. Therefore, it is important to consider an industrial Ethernet switch with proven redundancy capabilities to ensure network uptime and prevent ship operations from being disrupted.

Furthermore, devices in ECSs are required to be rugged and resistant to EMI/EMS in engine rooms that may have extreme, harsh operating conditions with fluctuating temperatures and high humidity. In addition, the devices must pass functional tests that follow the IACS UR E10/IEC 60945 standards, and must conform to international maritime standards such as DNV GL, ABS, and LR to ensure design and verification quality.

Moxa’s Solutions

Moxa’s EDS-600 Series supports QoS and IEEE 1588v2 PTP for precise control, ensuring network reliability across the whole integrated ECS. The EDS-600 Series also features Turbo Ring redundancy, ensuring network uptime and preventing ship operations from being disrupted. As most of the switches are installed in the engine or engine control rooms, the EDS-600 Series is design-ready for durability in extreme harsh environments with strong vibration, high EMC, and wide operating temperatures; it is compliant with IACS UR E10/IEC 60945 standards for harsh environments The EDS-600 Series has passed international marine certifications such as DNV GL, ABS, and LR to guarantee the reliable and safe operation of equipment used on ships.

For more information about the products, click to read

EDS-600 Series: Compact modular managed Ethernet switches

CM-600-4TX-PTP: 4-port Fast Ethernet interface modules for EDS-600 Series Ethernet switches

For more on marine applications, please download this IIoT Blueprint for Smart Ships:

https://www.moxa.com/support/request_catalog_detail.aspx?id=3629