Thanks to technological advancements that realize the potential of Industry 4.0, factory operators are investing more resources into the development of smart factories for enhanced operational efficiency. In fact, a recent study showed that the smart factory market is expected to grow 9.33% during the forecast period from 2021 to 2026. But before businesses can reap the benefits of smart factories, operators need to gain visibility of the production floor. This means they need to deploy more sensors and systems at production lines so that engineers can collect sufficient information, develop analytics, and ultimately take appropriate actions and improve efficiency.

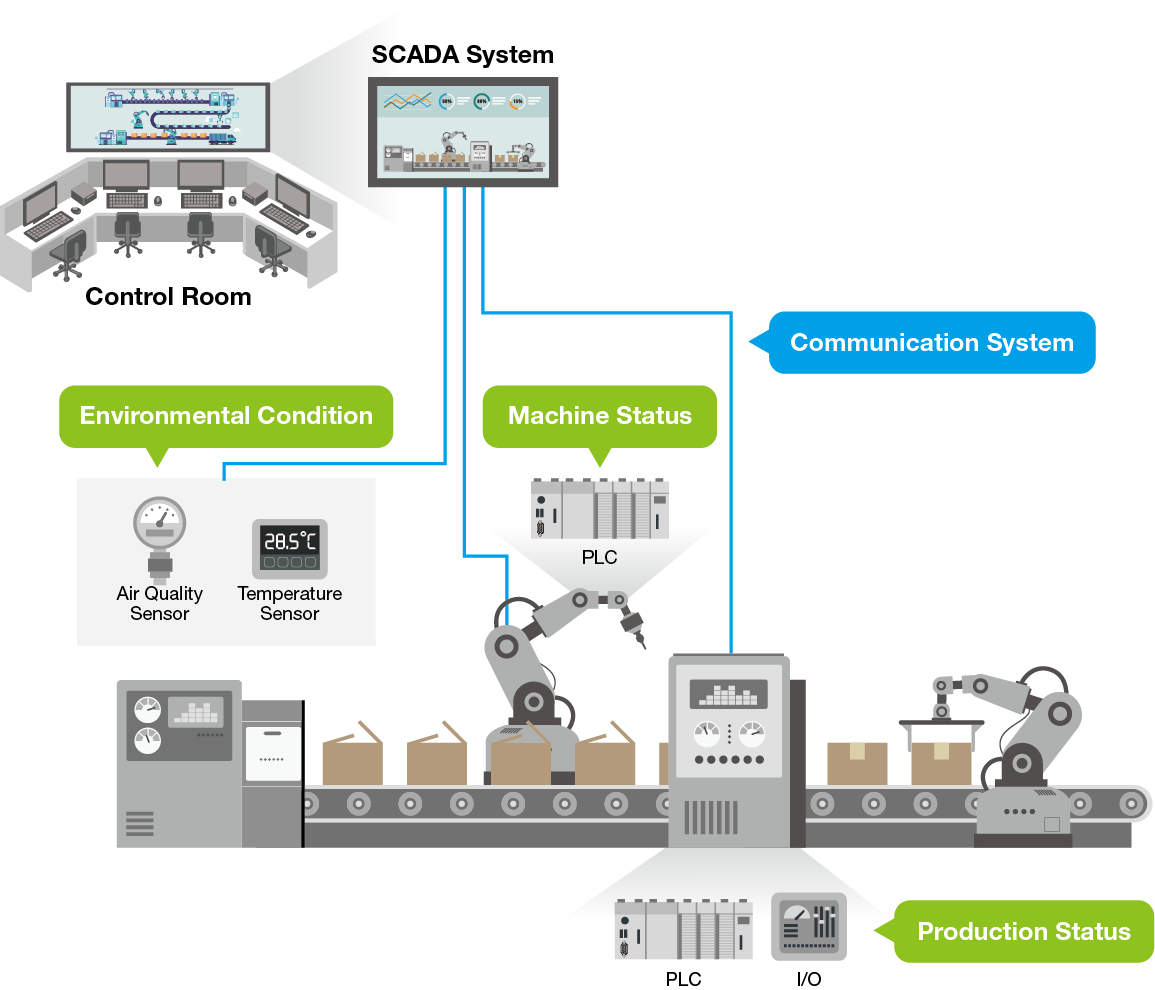

Developing a holistic view for your production lines requires different types of information. For instance, the production status of each production line informs you of how the line is performing and whether any potential or existing backlogs exist. By monitoring the real-time production process, you can improve your chances of eliminating potential downtime and enhancing productivity. In addition, tracking the operating condition of machines can help you arrange maintenance tasks without unwanted surprises. Furthermore, additional sensors can be deployed in production lines to collect temperature and humidity information to help minimize the likelihood of interruptions due to environmental factors.

No matter what kind of information you are planning to collect to achieve the goals of your ideal smart factory application, enabling smooth communication between production lines and the control center can present major challenges for engineers. Without a reliable connection and a solid network implemented between remote sites and the control center, operators cannot receive complete and accurate data for comprehensive planning and optimizing operational efficiency. Here are some suggestions you can consider when enabling connectivity for your production lines.

Evaluate Your Connectivity Requirements Thoroughly

When enabling connectivity for your production lines, you need to know what communication interfaces and protocols your field devices use, as well as what systems these devices need to communicate with. The following three scenarios are commonly seen when getting started.

- Retrieve operating information from legacy devices. Your legacy machines are specifically designed to serve production purposes reliably in your factories for decades, but they often come without network interfaces, or they only come with legacy communication interfaces such as serial. Use sensors to capture production information for devices that do not have any communication capability or consider a serial-to-Ethernet solution to retrieve data from legacy devices.

- Monitor your production status from the control center. Your production lines are usually controlled by engineers through a PLC and HMI located at the field site. When the central system also needs to control and monitor your production lines, they must be able to understand and communicate with the field PLC and HMI. However, machine vendors often adopt communication protocols that might not be compatible with SCADA systems. Such scenarios require a protocol conversion solution to enable communication between the SCADA system and the PLC and HMI in the field.

- Minimize impact from environmental factors. There are various kinds of sensors that can be used to measure environmental conditions, such as the temperature, humidity, and air pressure. These sensors come with multiple I/O interfaces and you need a remote I/O solution that can easily collect information. In addition, pay attention to the supported protocols for your remote I/O solution and choose the one that fits your SCADA system.

No matter what kind of scenario you encounter, the bottom line is there will be a variety of connectivity requirements that need to be fulfilled before you can receive data to improve your operational efficiency. You should carefully evaluate the connectivity options you have and choose the one that not only gets your devices and systems connected, but also enables smooth communication with minimal maintenance effort.

Deploy a Reliable and Flexible Network for Real-time Monitoring

Enabling a smarter production line requires stronger network capacity and better visibility. When planning your network communication, carefully assess your demands on transmission bandwidth, network control capability, and manageability for each network node. First, calculate your network bandwidth requirements. Connected production lines generally deploy more sensors and systems that generate substantially more data. Huge amounts of data not only require sufficient transmission bandwidth, but also need redundancy to avoid packet loss due to unexpected network downtime.

Second, your networking devices require support for communication protocols at both the field site and the control center in order for engineers to monitor and take actions in real time. In addition, if you are developing adaptive production control systems or have time-critical processes in your production lines, you can consider developing your networks based on time-sensitive networking (TSN), the standard Ethernet unified infrastructure, to deliver your commands to the right place at the right time.

Finally, deploying numerous network devices leads to tremendous installation and maintenance effort. This is something you should take into consideration because it is important that you should find an efficient solution that simplifies your networking management.

Don’t Overlook Cyberthreats

The growing number of cyberattacks targeting industrial applications in recent years has also made cybersecurity more important than ever. In fact, a recent survey showed that 4 in 10 manufacturers indicated that their operations were affected by a cybersecurity incident in the past 12 months. Threats are everywhere, including unauthorized access, unwarranted programs, and denial-of-service attacks that could lead to disruption of a production line. To mitigate security concerns, the first thing is to verify the security level of your networking devices. Use a checklist to verify if you are choosing a product that is secure-by-design in the first place. In addition, network segmentation is essential to slowing down threat propagation in the event of an actual cyberattack. Ultimately, it is crucial to remember that security is a journey, not an one-time event. Constantly monitoring your devices and security status and performing vulnerability scans on a regular basis can give you more control over your security posture before mitigation is required.

As a leading expert in industrial networking, Moxa has helped customers around the world develop smooth and secure communication to control and monitor their production lines. Download our case studies and see how other companies develop communication systems for their production lines with Moxa’s solutions.

Need help selecting connectivity or networking products for your project? Download our E-book and learn about the key criteria for choos ing the right products for your needs.