In substations, real-time monitoring is always of critical importance. However, for substations whose operations run on many legacy devices, real-time monitoring can be an enormous challenge for operators. While most substations are open to the idea of retrofitting, tight budgets curtail them most of the time. For these budget-challenged substations, the ideal solution is one that bridges a legacy infrastructure to an IEC 61850 network without breaking the bank.

The Complications

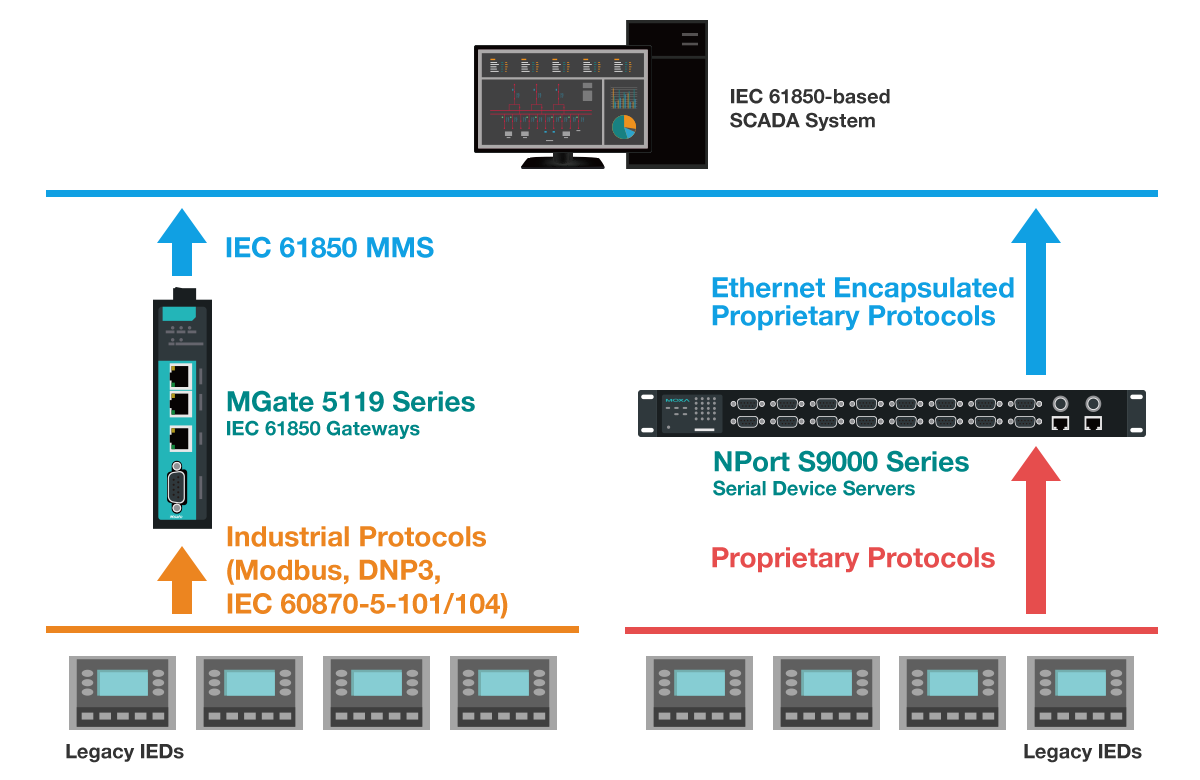

To have a better understanding of these substations’ dilemma, let’s take a closer look at the key aspect. Many remote terminal units (RTUs), human-machine interfaces, switches, and intelligent electronic devices (IEDs) installed in substations are from different vendors. They usually use proprietary or industrial protocols, making it extremely difficult for a power SCADA system to monitor the entire station. These days, new power SCADA supervision commonly supports the IEC 61850 MMS protocol. Thus, operators can bridge the communication between field devices and an IEC 61850-based power SCADA system so that they can monitor power quality in real time. In addition, the increasing number of cyberattacks at substations makes network communication security more important than ever. Subsequently, operators are looking for a secure communication solution that will reduce security concerns when they are retrofitting power substations.

Streamlining Communications for a Variety of Industrial Protocols

Mission-critical IEDs need to communicate with your power SCADA systems directly so that operators can monitor power quality in real time and take immediate actions when accidents happen. Compared with computing platforms, communication gateways are a cost-effective solution as they have a variety of built-in power industry-related protocols, such as IEC 61850 MMS, Modbus RTU/TCP, DNP3 serial/TCP, IEC 60870-5-101, and IEC 60870-5-104. These communication gateways easily bridge the communications between the IEC 61850-based SCADA systems and the different legacy IEDs used in your substation automation systems.

However, when you are using gateways to bridge communication between a variety of industrial protocols and the IEC 61850 MMS protocol, it takes tremendous time to edit the Substation Configuration Language (SCL) of IEC 61850 because of its complex settings. Fortunately, tools are available in the market to make this process more efficient. Therefore, consider adopting one of these useful engineering tools to simplify the complexity of editing SCL files when you are dealing with large-scale substation retrofit projects. However, an additional budget is required for this purchase.

Monitoring Proprietary-based Field Devices Without Replacement

Most certainly, substations operating decades have legacy devices running proprietary communication protocols, and it is not cost-effective to replace all of them at once. If you need to upgrade your substation automation systems to modern Ethernet-based SCADA, monitoring these field devices with minimal cost and effort is essential. Adopting a connectivity solution such as serial device servers easily helps you develop transparent connectivity between your IEC 61850-based power SCADA systems and proprietary-based field devices. This way, power SCADA monitors these legacy proprietary-based field devices by decapsulating Ethernet proprietary protocols.

Moxa’s Solutions

Moxa, as an edge connectivity solution provider, provides a variety of connectivity solutions for your different application demands. To streamline communication, our MGate 5119 Series is an easy-to-use substation gateway. It not only establishes communication easily from Modbus, DNP3, IEC 60870-5-101, and IEC 60870-5-104 devices to IEC 61850 communication networks but also supports NTP time synchronization functions to provide data with a consistent time stamp. The MGate 5119 Series also supports a built-in SCL file generator that easily completes SCL files for your substation gateways. Therefore, you don’t need to spend time and money to look for additional tools.

To monitor proprietary-based field devices, our NPort S9000 Series is a serial device server that migrates serial IEDs to an Ethernet-based infrastructure for legacy substation retrofits. The NPort S9000 Series supports up to 16-port serial interfaces, 4-port Ethernet switching, and Ethernet-encapsulated proprietary protocols to easily bring your field devices to SCADA systems. In addition, the NPort S9000 Series supports NTP, SNTP, IEEE 1588v2 PTP, IRIG-B time synchronization functions, synchronizing not only the NPort S9000 but also the legacy field devices.

When you visualize your substation networks, it is essential to enhance device security on the networks. Our serial device servers and protocol gateways address your security concerns when you connect your field devices to networks. Both devices incorporate IEC 62443 and NERC CIP guidelines, featuring security embedded functions, such as user authentication, accessible IP lists, and secure device configuration and management through HTTPS and TLS v1.2 to protect your communication devices from unwanted access. What’s more, our solutions perform vulnerability scan periodically to take necessary actions, such as security patches, to enhance device security for your substation networks.

In addition, both of our serial device servers and protocol gateways comply with IEC 61850-3 and IEEE 1613 to ensure reliable operation in your substation environments. For more detailed features of our IEC 61850 MMS solutions, use the selection table below to find the product you need.

|

Product Comparison

|

NPort S9000 Serial Device Servers

|

MGate 5119 Series IEC 61850 Gateways

|

|

Northbound communication protocols

|

Ethernet-encapsulated proprietary protocols

|

IEC 61850 MMS

|

|

Southbound communication protocols

|

Serial-based proprietary protocols

|

Modbus RTU/ASCII/TCP, DNP3 Serial/TCP, IEC 60870-5-101/104

|

|

Device management protocols

|

IEC 61850 MMS and SNMP

|

IEC 61850 MMS and SNMP

|

|

Network management tools

|

MXview network management software

|

MXview network management software

|

|

Security features

|

NERC CIP

|

NERC CIP

|

|

Certifications

|

IEC 61850-3, IEEE 1613

|

IEC 61850-3, IEEE 1613

|