Without exception, the competitiveness of any factory is determined by its two pillars: productivity and efficiency. Since the 1960s, overall equipment efficiency (OEE) has been the benchmark for measuring productivity in factories—more specifically, identifying operating machines that do not run on full capacity so that the necessary fixes can be made. In turn, a truly effective OEE depends on the visibility of machines in the control room. In this article, we take a closer look at the challenges that needs to be overcome to make the operating data of these machines more visible.

A Mixed Bag of Legacy and Modern Machines

Visibility of machine tools on a shop floor relies on how much information, such as machine status, these machines provide. Most of the time, this kind of information is provided natively by modern machines as the required parameters are already encoded within them. When it comes to legacy machines, we are less lucky because back in the day retrieving data about machine status was not the trend, and machines were only designed to do their job, for example, cutting, lathe, etc.

That Old Devil Called Interoperability

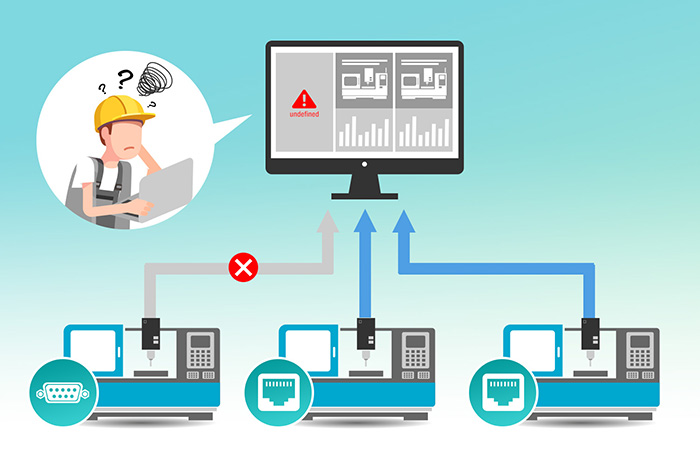

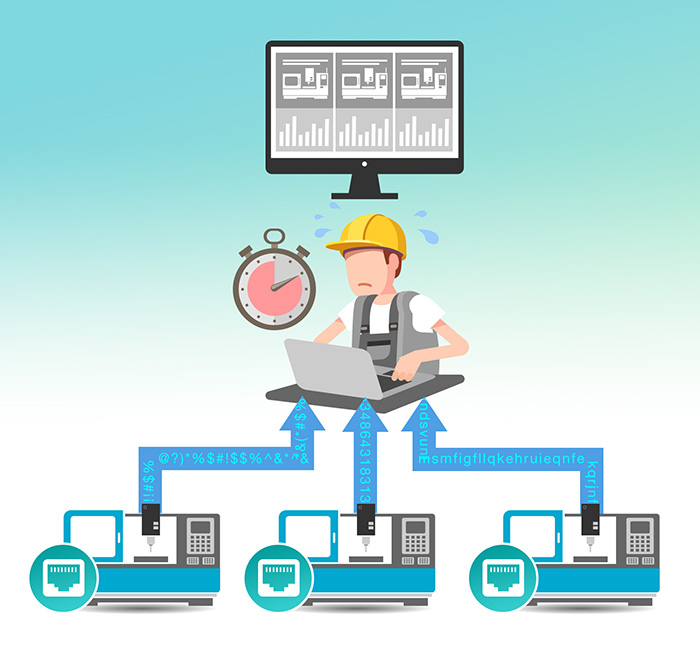

Even though modern machines are able to provide valuable machine information, it does not make monitoring on a shop floor straightforward. Different brand types, each using its own set of protocols, complicate operations as the output data from these different machines are not always interoperable with a singular software platform, making data analysis a herculean task. Consequently, these interoperability issues require concerted efforts from system integrators to make the required data more accessible.

Unify OT Data with MTConnect

Since 2008, MT Connect, an open and free protocol, has been increasing the interoperatibility between manufacturing equipment of different brands with software applications from different providers. MTConnect is a read-only standard, meaning it only defines the readings of data from control devices, which make it more than suitable for machine data collection.

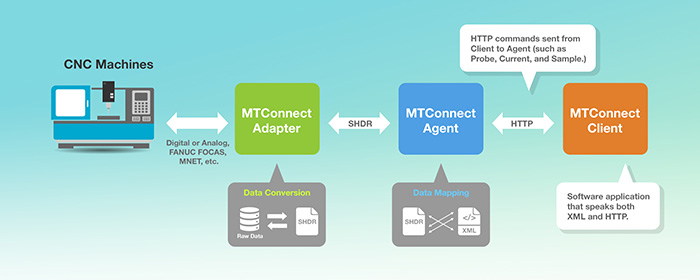

Key elements that make up an MTConnect-ready application include an MTConnect Adapter, an MTConnect Agent, and an MTConnect Client. The MTConnect Adapter (could be either hardware or software) converts all the data that comes from a machine into a format that the MTConnect Agent recognizes (usually SHDR). The MTConnect Agent will then map this data to XML and allow the MTConnect Client to query the data through HTTP.

Implementation

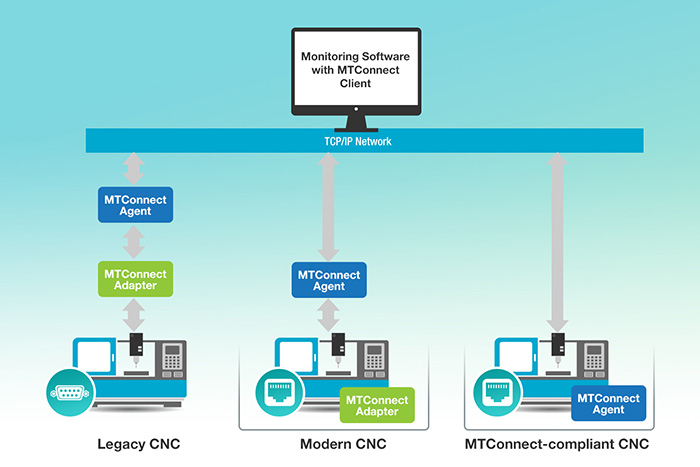

In recent years, a number of machine makers have started to manufacture MTConnect-compliant machines. However, a large number of CNC machines, with an average of lifespan of 25 to 30 years, or even longer, do not support MTConnect. Furthermore, a big portion of them communicates through serial interface only. For those modern machines with Ethernet communication interfaces that are not MTConnect compliant, controller manufacturers or system integrators may spend development efforts on MTConnect Adapters to enable MTConnect capability on these machines. For those machines that neither have an Ethernet communication interface nor come with the intended MTConnect Adapter developed for them, I/Os are commonly used to retrieve machine status, for example, via stack lights. However, few I/O solutions support MTConnect, yet again increasing the integration effort on the shop floor.

Moxa's Solutions

NPort IA(W)5000A-I/O Series has a built-in MTConnect Adapter and MTConnect Agent that provide flexible configuration capabilities for users to define input data into desired MTConnect tags, saving you great effort with the integration of your monitoring application.