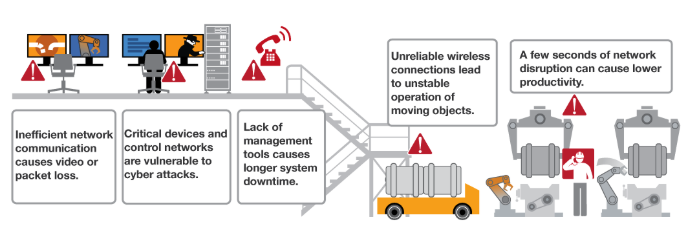

All of those involved in industrial automation are eager to reap the benefits of the Industrial Internet of Things (IIoT). However, before businesses can start deploying their networks, the correct infrastructure must be in place. We’ve identified five common concerns that engineers typically experience when they are deploying their industrial networks.Is Your Network Infrastructure Ready for the Industrial Internet of Things?

Concern #1: System Downtime

Two critical factors affect network performance at field sites: the quality and design of devices and network recovery times. Industrial networks are often deployed in harsh conditions, so the devices must be sturdy enough to withstand any environmental challenges e.g. extreme temperatures. In addition, industrial-grade recovery times are much better than enterprise-grade recovery times at reducing or even eliminating system downtime on time-critical operations.

Concern #2: Network Communication Inefficiency

The introduction of quad-play services (data, voice, video and control) on industrial networks has made transmission more complex and the networks now require much larger bandwidth. When building a network for bandwidth-hungry applications, most notably video, as well as for networks that are likely to expand in the future, it must be ensured that there is sufficient bandwidth available for smooth operations. Without sufficient bandwidth or a competently designed network, you could encounter video loss or packet loss.

Concern #3: Vulnerability to Cyberattacks

Users are very concerned about security on industrial networks as the more devices that are added, the higher the risk that one of the devices will become compromised. If the network does become compromised, the network might allow unauthorized personnel and even hackers to gain access. In 2015, an ICS-CERT report found that there were almost 300 cyberattacks involving US critical manufacturing infrastructure. Inadequate protection of your network makes it very vulnerable to such attacks.

Concern #4: Unstable Operation for Moving Objects

Engineers frequently note the importance of clients being able to roam smoothly between access points with minimal handover times; otherwise, this will cause unacceptable delays in the production process which will in turn cost businesses a significant amount of money. A Markets and Markets forecast found that the cost of plant operations can be reduced by up to 30% by applying automated factory floor systems. In order to realize this incredible potential, stable moving operation is the key.

Concern #5: Lower Productivity

Engineers need to collect real-time network information to be able to fix errors quickly. Moreover, it’s increasingly common for administrators to work outside of the control room even though industrial environments still require decisions to be made instantly in order to maintain high productivity levels. Businesses are starting to overcome this problem by allowing the administrator to check the network status on a mobile phone app and thus allowing them to instantly respond to events on the network.

Optimize Your IIoT Network Connectivity with Smart Network Infrastructure

Moxa has been involved in designing and deploying industrial networks for over 25 years and has developed advanced technologies to enable a smart network infrastructure that optimizes your IIoT network connectivity. Our solutions aim to achieve optimized performance, strengthened security, easy management, seamless mobility, and increased productivity. Learn more about how Moxa’s smart network infrastructure enables businesses to make better decisions when deploying or upgrading industrial networks.

Learn more about how Moxa’s smart network infrastructure enables businesses to make better decisions when deploying or upgrading industrial networks with one of the resources below:

Download FAQ: Is Your Network Infrastructure Ready for the IIoT

Visit Moxa’s IIoT network infrastructure portal.