Seamless Connectivity and Data Transparency in Smart Factories

Smart manufacturing requires complete transparency of data to enable end-to-end digitization of the production and supply chain. Many factory owners are integrating their facilities management systems with the smart factory system to achieve higher controllability and faster response times, and to maximize overall equipment effectiveness. This means a sharp rise in the number of end devices that need to be connected. Industrial computing solutions specially designed for the data acquisition needs of smart factories are bridging the gap between the IT and OT worlds by providing high-performance, reliable, easy-to-use solutions. We take a look at two typical applications in facility management and environment management to understand the pivotal role that computing solutions play in enabling Industry 4.0 in factories and preparing the ground for a future in big data analysis, self-managing devices and business intelligence.

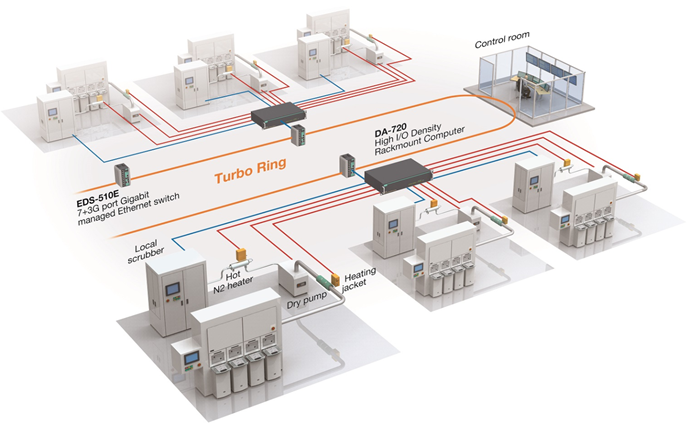

Efficient Device Control in Dry Pump Monitoring Systems

Device control systems, such as GIS, dry pump, and local scrubber systems, are critical elements of a facility management and control system (FMCS). Typically, there are hundreds of devices in an FMCS that need to be managed, with most of them located in remote areas. The management platform must have the ability to connect to all of these devices and should help optimize and maximize overall equipment effectiveness (OEE).

In addition, the system must enable protocol conversion between the various dry pump devices so that they can communicate with each other to enable faster response times. Real-time data acquisition, storage, and management will enable predictive system maintenance and minimize system downtime. Reliable network performance is a must in the harsh environments of a dry pump facility where electrical interference is common.

Moxa’s DA-720, a high-performance industrial-grade x86 platform, is ideal for this application:

- Intel® Core™ i7, 2.6 GHz, dual-core CPU or i5, 2.4 GHz, dual-core CPU (Skylake)

- High I/O density with up to 22 Gigabit LAN ports plus 10 serial ports, or 14 Gigabit . LAN ports plus 18 serial ports

- Moxa's fanless heat dissipation technology

- PRP/HSR support to establish network redundancy for high network availability

- Proactive Monitoring and Smart Recovery support for easy maintenance

- Remote control functionality for controlling devices at unmanned sites

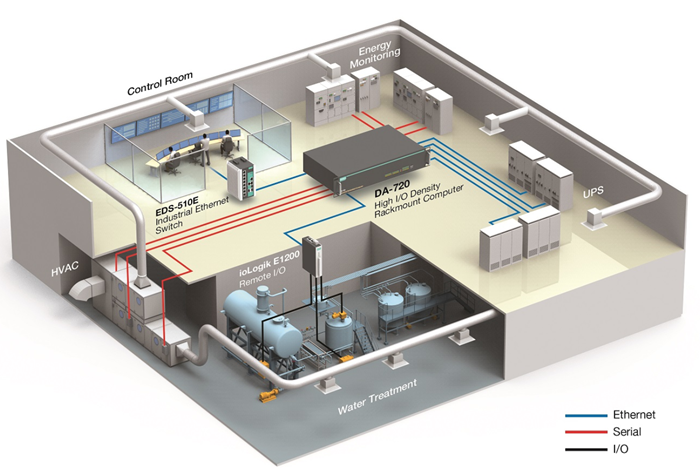

Power and Environmental Monitoring System

Environmental control and monitoring systems, such as UPS, HVAC, access control, lighting control, and fire alarm systems, are critical elements of a facility management and control system (FMCS). When monitoring and analyzing the large amount of diverse data from these systems, it is essential to select a reliable, high-performance computing platform that is optimized for data-acquisition and protocol conversion.

Data acquisition and computing solutions used in FMCS must provide high system stability and longevity. Remote control functionality to monitor and control IIoT devices, especially ones installed at unmanned sites, is a must. In addition, the system should be able to provide seamless performance in the high-noise environment of an industrial facility.

Moxa’s DA-720 rugged computers come with a fanless design for longevity, provide level-4 EMC protection, and include Proactive Monitoring and Smart Recovery functions to help minimize system downtime. These computers support remote control functions to manage devices and equipment located in remote, hard-to-reach areas.

To learn more about the DA-720 computing platform, download the product brochure.