For factories to enjoy peak overall efficiency effectiveness (OEE), device connectivity is essential to collect precise data. To improve the availability and performance rates of equipment as well as the quality of their output—the three factors that constitute OEE—factories can now take advantage of a number of connectivity solutions to capture valuable data in order to boost production.

Integrated Solutions

OEE is authoritative because it carries a lot of information within one number; therefore, it is widely adopted as a yardstick to improve production on shop floors. A three-pronged approach that examines the availability, performance, and quality rates of machines gives factory managers a better understanding of what needs to be changed in their manufacturing process to reach peak production. Once problem areas have been identified, new technologies can be sought to address shortcomings in manufacturing processes.

Solutions to improve the availability rate of machines

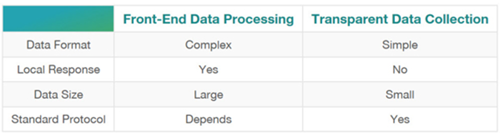

Interpreting the working status of machines on a factory floor at all times is crucial to reduce downtime and improve network availability. Hence, real-time data is required to implement predictive maintenance. During production, different types of data on machine status can be generated, such as machine vibration, motor current, tool level, coolant level, and many more. Based on this data, machine maintenance engineers can schedule maintenance tasks in advance (predictive maintenance) to prevent any unexpected machine downtime. However, this data presents itself in different forms. One is streaming data, which is transmitted in large volumes and requires preprocessing before it is sent to a back-end system. The other is status data, which is transmitted in small volumes and via a transparent method without any preprocessing. Thus, different data collection methods are required.

For streaming data, the best method is to use front-end data processing to reduce the amount of data sent so that only valuable data is sent to the back-end system.

Solutions to improve the performance rate of machines

In a mixed-model production line, a programmable controller that supports multiple functions and interfaces—such as serial, DI/O, and AI/O—is a huge asset. A controller helps categorize production tasks by automatically retrieving the task sequence from a manufacturing execution system (MES). For example, tools are identified by an RFID tag, the controller retrieves the corresponding production method from the MES via RESTful API, and then notifies all the relevant machines via an industrial protocol such as EtherNet/IP, PROFIBUS, or Modbus. The production information can be retrieved via an IT protocol, such as RESTful API.

Solutions to improve the quality of machines’ output

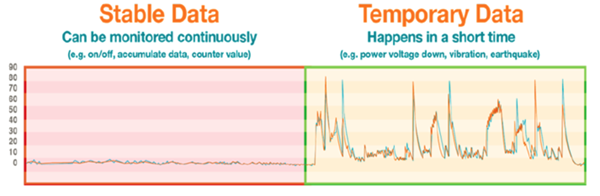

Perfect production is characterized by zero defects, and once again, production data is the key to achieve zero defects. Two types of data are applicable: stable data (on/off status) and temporary data (generated over short periods and needs to be recorded without any missing parts). When the latter is generated, an alert should be sent immediately to operators that an interruption is occurring. As the quality of production is reflected in this temporary data, the challenge is to capture this data precisely. A ruggedly designed IIoT controller can collect precise data in harsh environments to keep line managers up-to-date about the status of all devices in the field.

Moxa's Solutions

In addition to the aforementioned solutions, there are even more options available to factories to upgrade their production technology and improve their OEE. For more information about these solutions, read our white paper: Device Connectivity Is the Key to Optimal OEE in Industry 4.0.