Introduction

Digitalization Optimizes Shipping Routes

Within the marine industry, fuel and labor costs are increasing and ships are frequently subjected to levies, which is resulting in tighter margins throughout the entire industry. In order to address this issue, a shipbuilding company wanted to digitalize information on their ship to help reduce costs and improve fuel efficiency. However, this was difficult to achieve because shipping environments are inherently unpredictable and many obstacles needed to be overcome before a suitable solution could be deployed. China’s first certified smart ship, Great Intelligence, features a brand new ship architecture and operational concept, which allowed the shipbuilding company to introduce a more secure, economic, and environmentally friendly ship to the world.

A few years ago, smart ships were still a concept, but over the last couple of years have become a reality, which has started a new and exciting era within the marine industry. In order to develop an intelligent Integrated Navigation System (INS) that can continuously collect data while the ship is in motion, optimize the shipping route, and also decrease fuel consumption requires industry expertise. The first step to achieving this is a reliable and secure solution that is able to collect and analyze data in real time from hundreds of sensors and ensure accurate data processing in the constantly changing environment onboard a ship.

System Requirements

- Collect and process data from over five hundred sensors to facilitate safe sailing, ensure the most appropriate route is taken, and perform predictive maintenance to keep downtime to an absolute minimum.

- Develop an intelligent INS that can reliably collect wind direction and ocean current data and then utilize this data to suggest the optimal route.

- A secure network to ensure smooth data filtering and transmission when using different subnets.

- All devices have to be able to withstand weather extremes anywhere in the world to ensure they do not get disconnected from the INS.

- Multiple maritime certifications to ensure seamless entry into sea ports around the world.

Moxa Solution

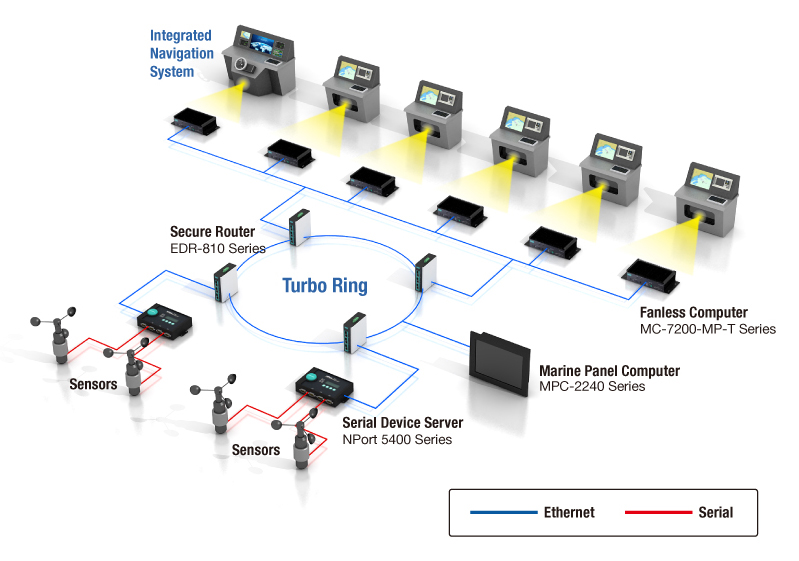

Ensure Smooth Transmission of Data from Sensors to the Control Center

To ensure that data such as wind direction and ocean current is collected reliably and securely from sensors, Moxa’s serial-to-Ethernet solution (NPort 5400 Series) and industrial secure router (EDR-810 Series) connect with multiple serial-based sensors and transmit the data to an Ethernet network through multi-layered security. Once the INS receives the data, Moxa’s marine computers (MC-7200-MP-T Series), which feature eight NMEA ports coupled with strong computing power, can process large amounts of data quickly to determine the ideal route for the ship to take. Furthermore, to ensure the ship operates to the best of its ability, Moxa’s panel computers (MPC-2240 Series) monitor automation systems to avoid system downtime, which helps ensure safe operation of the ship. In order for the system to remain stable throughout journeys, all of Moxa’s solutions are tailor made for the marine industry and include products with fanless, thermal, and industrial designs that can protect against corrosion from high humidity, salinity, and fog.

Ships that have intelligent control centers make sailing more efficient and significantly enhance the ships competiveness within the marine industry. By continuously collecting data and performing data analytics has allowed Great Intelligence to become an autonomous ship, which is a step closer towards the ultimate goal within the marine industry of being able to deploy unmanned ships.

Why Moxa

- A high-performance computing platform that can process large amounts of data collected from sensors and display high resolution images on an ECDIS-compliant screen in the INS.

- Our industrial secure router includes a high-performance firewall that prevents unauthorized connections from within the WAN without creating unacceptable amounts of latency when transmitting data.

- Devices that operate reliably in temperatures ranging from -40 to 70°C.

- Our devices are compliant with IEC 60945 Edition 4, IEC 61174, IEC 61162, and IACS E10 as well as the following maritime standards and certifications DNV GL, ABS, LR, NK, and CCS.