Introduction

A leading manufacturer of filling, bottling, and packaging machines utilized Ethernet switches and PROFINET technology to create an integrated industrial network. The use of the PROFINET protocol is common in manufacturing. However, before all of the benefits of Ethernet-based technologies can be taken advantage of, machine builders have to overcome a few challenges. One of the main challenges is that machines builders often come from a technical field of mechanics and electrical engineering and do not have much IT knowledge, so they find it difficult to work with the new IT infrastructures that are deployed. This manufacturer, based in Europe, is already using the protocol in its machinery and equipment. By using the PROFINET protocol, the company can increase the diagnostic capabilities of their PLCs, reduce the time it takes to build their machines, and deploy untrained staff to replace devices within a few minutes.

System Requirements

- Minimal IT knowledge required for easy migration from PROFIBUS to PROFINET

- The new switch must perform well on PROFINET networks

- The network must perform reliably all the time

Moxa Solution

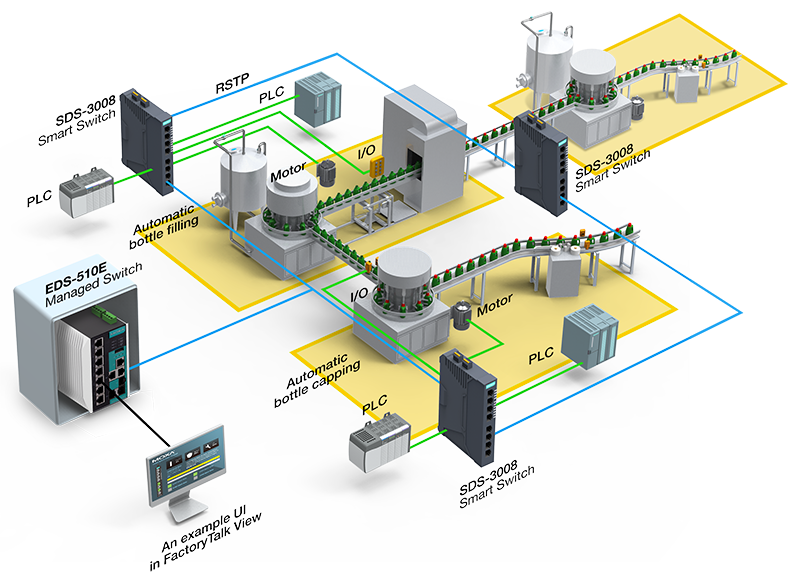

The company is able to meet all of the key project requirements by deploying Moxa’s SDS-3008, which is a smart switch that is capable of cyclically exchanging information with the PLCs over the PROFINET protocol. The machine builder only needs to load the GSD file into the PLC and does not need to perform any configurations. In addition, the PLC can automatically correct the name of the PROFINET device if it is not assigned correctly. This simplifies the first steps of machine development and saves the manufacturer time.

The SDS-3008 smart switches can be integrated with the PLC using SIMATIC Step 7 or the TIA portal. This allows the PLC to determine which ports are active, the status of the redundancy mechanisms and redundant power supplies, and the data transmission speed. The PLC can evaluate this information or pass it on to the HMIs. The information can be integrated directly in the programmer’s development environment, which generates added value for programmers and end users without the need for additional tools or interfaces.

Moxa’s portfolio of switches includes 8-port smart Ethernet switches for PROFINET networks. As the devices support PROFINET protocol, the switches can be directly integrated with the engineering software SIMATIC Step 7. Modern industrial control networks consist of a multitude of PLC models and Fieldbus devices, including SCADA systems at the management level for decentralized monitoring, and HMIs for on-site monitoring and control. Network components that use PROFINET enable fast and secure data transmission to deliver reliable network status information for decentralized analysis. The performance and reliability of the PLC network can be improved by using devices with high redundancy, fast boot up times, status parameters, and flexible topologies. The switches also support IEEE 802.1Q VLAN, port mirroring, SNMP, and alerts by relay output.

Why Moxa

- Supports the profile-based PROFINET protocol, which enables fast deployment, saving time and effort.

- A compact and flexible housing design to fit into confined spaces, such as control cabinets.

- Supports RSTP/STP for network redundancy.