Introduction

Industry 4.0 represents a general strategy for increasing production efficiency and reducing system downtime. Constructing a reliable and automated infrastructure is the most important prerequisite for achieving these goals. For example, deploying automated guided vehicle (AGV) systems for material handling allows factory owners to enhance operational efficiency and increase productivity. However, system stability can be a key concern. Given that the warehouse AGVs are constantly on the move, wireless clients installed on the moving AGVs should not only be able to roam seamlessly between wireless APs, but also endure the vibration resulting from the AGVs’ movements. Moreover, to ensure smooth plant-wide communication, industrial-grade Ethernet switches that support industrial protocols and can tolerate field-site environments are required.

One of our customers, a leading provider of turnkey material handling systems in the US, provides automated conveyors and automated guided vehicles (AGVs) to large factories that produce corrugated, folding cartons, and bottles and cans. Their key requirement is building a highly reliable system to ensure nonstop plant operation.

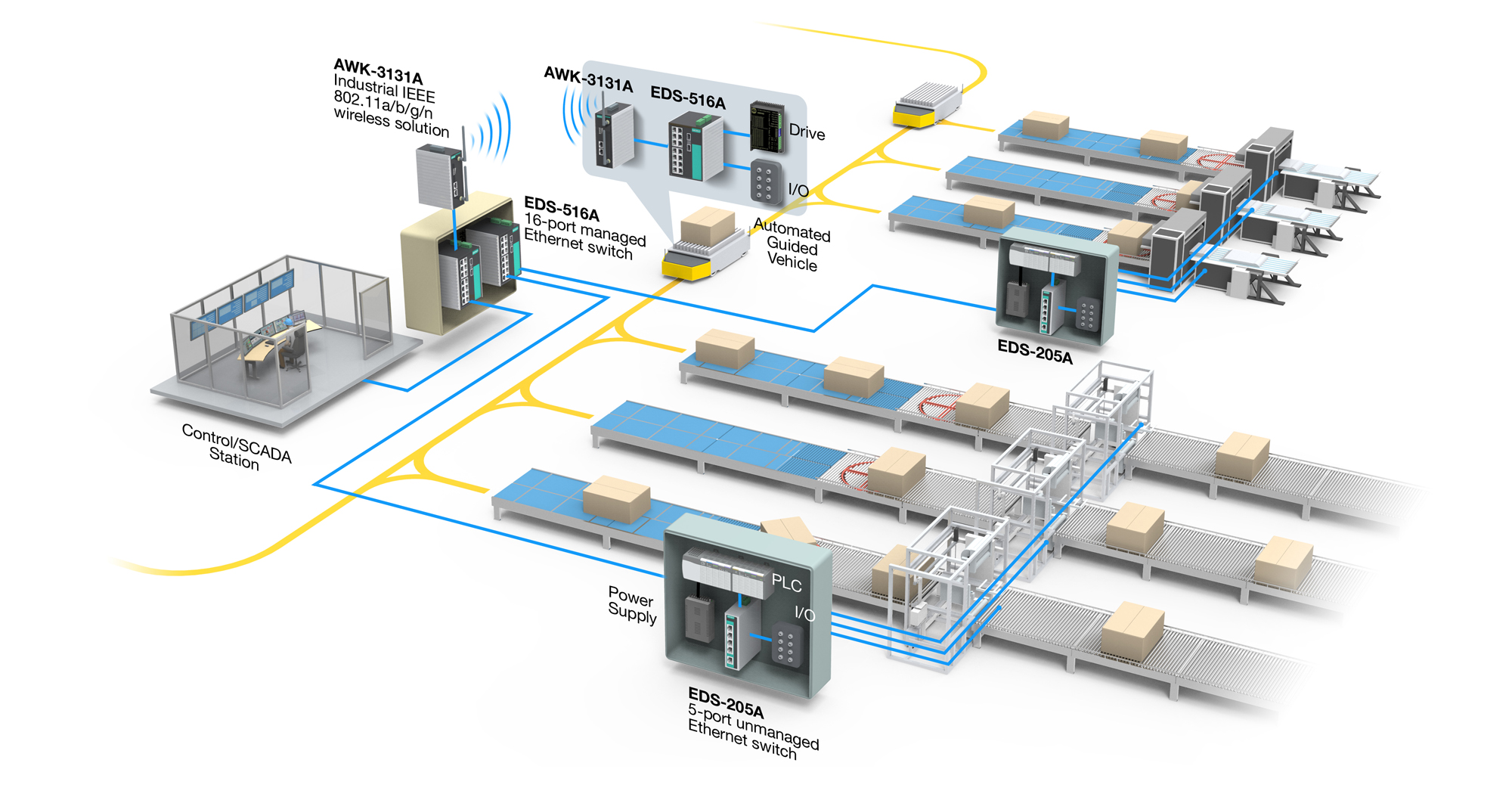

In this project, the industry leading Allen-Bradley EtherNet/IP programmable logic controller (PLC) was used for control systems, but they also selected Moxa’s industrial Ethernet switches to build two reliable industrial networks to implement their automated material handling systems. The first network is an EtherNet/IP control network for PLCs, IOs, and SCADA connections with EDS-516A Ethernet switches that support the EtherNet/IP protocol. The second network is the backbone network that handles plant-wide communication. They also deployed Moxa’s wireless AWK-3131A series to establish robust industrial wireless communication for AGV control.

System Requirements

- Interoperability with Allen-Bradley EtherNet/IP PLCs, and EtherNet/IP support for SCADA monitoring.

- High-port-density, robust industrial Ethernet switches to ensure the reliability of the control and communications network.

- Always-available industrial wireless communication for AGV control.

- Easy backup and restoration of configuration files to reduce downtime.

Moxa Solution

- Moxa’s EDS-516A industrial-grade managed 16-port Ethernet switches interconnect the control network and plant-wide communications network.

- Moxa’s switches support EtherNet/IP for integrating the Allen-Bradley PLCs with the SCADA system.

- The ABC-01 configuration backup dongle enables zero-time configuration of replacement switches.

- Moxa provides AWK-A series robust industrial wireless access points for reliable AGV control.

Why Moxa

- Industrial-grade design and durability to withstand extreme conditions

- One-stop-shop solution makes network communication and configuration simple, reliable and cost-effective