What if the key to elevating your factory's productivity to the next level isn't in new machinery, but in the data you're already generating? For too long, operational technology (OT) data has been a "silent partner" in manufacturing, confined to individual machines and on-premise PLCs. But now, a renewed ability to collect, transmit, and analyze this data is becoming the next competitive frontier. This shift is happening because of the growing demand for more precise motion control, predictive analytics, and real-time decision-making. This topic was discussed at length in the recent Manufacturing Happy Hour podcast episode: How AI is Reshaping Security and OT Network Requirements. The way we use OT data today is very different from how we used it in the past. Especially with data-hungry AI applications on the rise, OT data and networks deserve more attention.

Expanded OT Data With a New Purpose

OT data typically refers to data from sensors, meters, controllers, or monitoring platforms, such as SCADA systems. In the past, OT data was primarily used for monitoring and controlling automation systems. Its main purpose was often tied to specific goals, such as:

- Checking whether the valve of a sewage treatment tank is open or closed.

- Monitoring whether the daily output of production equipment meets expectations.

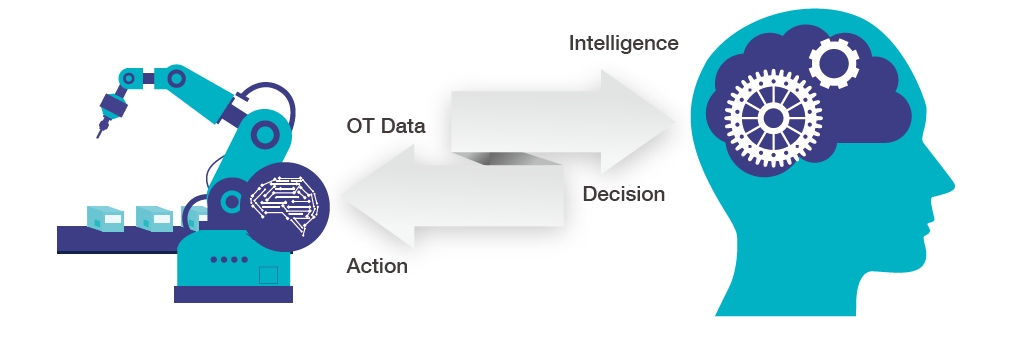

Now, OT data is a powerful asset used by other digital systems and is becoming an integral part of analysis and decision-making efforts. AI models, for example, can analyze real-time OT data from field devices such as vibration, temperature, and current power draw ratings to predict a machine's failure before it even occurs. This enables proactive maintenance, reducing unplanned downtime, and increasing overall equipment effectiveness (OEE). This novel role of new and existing OT data in empowering decision makers with data-driven insights is helping pave the way for more agile, responsive, and intelligent manufacturing environments.

OT data’s reach has expanded from controlling end devices to business decisions

OT data’s reach has expanded from controlling end devices to business decisions

Is Your OT Network Limiting Your Strategic Vision?

Today’s data-driven networking landscape opens up a whole new realm of possibilities. However, whether you’re striving for predictive maintenance, real-time process automation, or AI-powered decision-making, everything hinges on your ability to leverage the vast amounts of data needed to do so. Plenty of manufacturers find themselves bottlenecked by legacy OT networks that were not designed to accommodate the scale, speed, and connectivity demands of modern industrial applications, especially data-intensive AI systems. Here are some common limitations and challenges you might face on your way to modernizing your OT networks.

- Legacy network infrastructure: Many operational networks rely on decades-old technology with very limited bandwidth. These networks are not equipped to handle today’s volume, speed, or data requirements for more resource-intensive applications.

- Air-gapped isolation: Most legacy OT networks were often deployed as standalone, "air-gapped" systems to enhance security and prevent external interference. Now, with strategic initiatives that rely on interconnected and seamless data flows, this siloed design adds a new layer of complexity when integrating these systems.

- Growing reliability requirements: More than ever, stable and uninterrupted transmission of huge OT data volumes is critical for achieving real-time control and adaptability. This is especially true for high-precision applications where even the slightest delay or data loss could spell disaster. In addition, some industries operate in harsh, outdoor environments with extreme temperatures and electromagnetic interference. Sustaining reliable data streams for lengthy periods under such conditions is difficult.

- Increased security threats: Connecting legacy OT systems to larger enterprise networks and the Internet presents security challenges. Without proper cybersecurity measures, critical data could be at risk and potentially threaten operations. Whereas air-gapped networks offer security through isolation, network designers now need to consider how to deal with the host of new vulnerabilities of cloud-connected OT systems.

To put these limitations and challenges into perspective, let's look at two specific real-world examples:

- Intelligent Transportation Systems (ITS): Expanding traffic monitoring infrastructure with more cameras allows for more accurate and real-time traffic analysis. Nowadays, traffic cameras support increasingly higher resolutions, such as 4K. Passing on that live video data to a remote control center for analysis requires a network that can seamlessly handle immense amounts of video data without delay.

- Semiconductor Manufacturing: Achieving the strict precision required for advanced processor manufacturing relies on real-time control made possible through countless high-resolution cameras. A robust and reliable network foundation is essential for uninterrupted transmission of data streams and high-resolution imagery without any loss or latency, providing critical process visibility.

The Path to a Futureproof OT Network

There’s a trove of untapped value in your OT data; you just need the right tools to tap into its full potential. A robust OT network capable of collecting and processing vast amounts of data from interconnected systems empowers advanced applications such as AI and machine learning. Here are some questions and recommendations to help you gauge if your OT network is ready for the future of industrial networking:

- Can my network handle growing volumes of OT data and connectivity needs? Your network should have enough bandwidth and connectivity options to support data-intensive applications like high-resolution live video streams for quality control and large volumes of diversified data for AI models, while also planning for future demands. A futureproof network should be built around high-bandwidth and scalability with future expansions in mind. For example, ring topology technologies let engineers effortlessly add new devices to production lines without revamping the entire network.

- Is my network capable of transmitting critical OT data uninterruptedly? Always select industrial-grade network equipment that meets the unique environmental demands of your industrial applications to ensure optimal reliability. Factor in operating conditions such as extreme temperatures, electromagnetic interference, and explosion-proof requirements. Just as important is incorporating robust redundancy capabilities to minimize potential downtime. This involves measures such as embedded device redundancy and redundant power supplies.

- Is my OT network and data protected enough against cyberattacks? As OT networks become more interconnected, a defense-in-depth strategy is essential for protecting critical OT data and operations from a whole new range of cyberthreats. This approach involves creating multiple security layers—including firewalls, intrusion detection systems, network segmentation, and access control policies—to secure both the network and the data it carries.

- Do I have full visibility and control over my OT network? When networks become more interconnected and grow in scale, getting visibility over your operations can become challenging. Centralized network management tools provide a single-pane-of-glass interface for monitoring, troubleshooting, and configuring the entire network. This offers you full control over your network and reduces both complexity and operational overhead.

The OT landscape is changing every day. To unlock the immense value of your OT data for a future driven by AI and other technological advancements, you need a futureproof OT network that is built to stay ahead.

Ready to Get Started?

Explore our helpful tips to navigate each key checkpoint and futureproof your OT network. Download our latest Your Playbook for a Scalable and Reliable OT Network today.