Introduction

In order to create a comfortable travel experience for passengers, operators often use remote I/O devices to control and monitor onboard systems to ensure they operate smoothly. A train operator based in Germany needed a reliable remote I/O device to monitor their onboard HVAC and lighting control systems. The remote I/O devices required rail certifications to ensure they were capable of enduring harsh onboard environments. Finally, the products needed a compact form factor so that they could fit into the cabinets already installed on the trains.

System Requirements

- Devices designed in accordance with the EN 50155 standard and a rugged design to withstand harsh onboard environments

- Remote I/O devices with a compact form factor that can fit inside small cabinets on trains

- Daisy-chain network topology to remove the need for extra wires and reduce costs

Moxa Solution

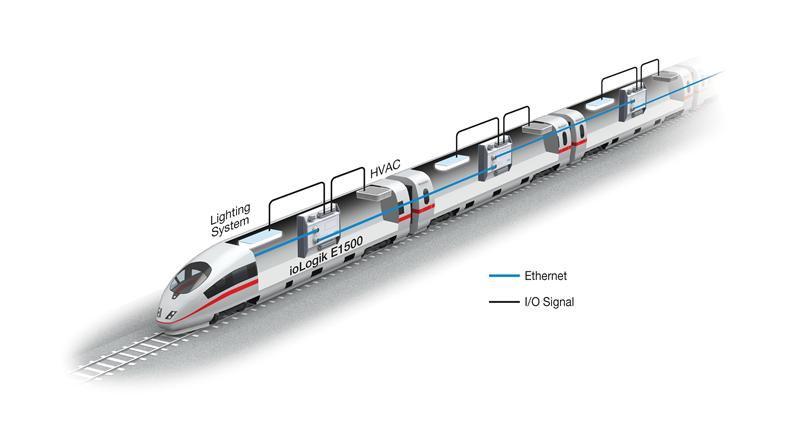

In order to enhance passenger safety, there are multiple systems on trains such as HVAC, lighting control, door control, and fire detectors that require reliable remote I/O to control system operations and monitor the status of devices. Thus far, 580 of Moxa’s ioLogik E1500 Series remote I/Os have provided reliable onboard condition monitoring for HVAC and lighting systems on several trains in Germany. The rugged metal case of our ioLogik E1500 Series met the relevant portions of the EN 50155 standard and the PCBA coating ensured that the product was able to withstand harsh onboard environments. In addition, the channel-to-channel isolation on the DI inputs protected data communication from unexpected surges.

The compact form factor of the ioLogik E1500 Series made it ideal for deployment in train cabinets that had space constraints. Moxa’s products allowed network operators to minimize costs because they could deploy a daisy-chain topology that did not require extra wiring. By deploying our ioLogik E1500 Series remote I/Os, train operators were able to ensure that the onboard HVAC and lighting systems operated reliably.

Why Moxa

- Products with a rugged metal case that comply with the relevant portions of the EN 50155 standard to ensure suitability for use on trains

- Compact design that fits easily into cabinets on trains

- Daisy-chain network topology that reduces costs

- Channel-to-channel isolation (DI only)

- PCBA coating to ensure smooth operations in harsh environments

- Quick customization and ongoing support