Introduction

Computer Numerical Control (CNC) machines are used in a variety of manufacturing operations to automate machine tools according to programmed commands. Although a factory in China already used Moxa’s NPort 5110 to send instructions in the form of TCP/IP packets to its CNC machines, maintenance engineers still had to visit each machine to ensure proper operation and perform routine maintenance tasks. Having the right information at the right time about these machines can help factory managers allocate enterprise resources more efficiently and improve production output. Since every second a CNC machine is idling, off line, or shut down for maintenance translates into lost profits, the factory needed a way to monitor the status of its CNC machines to optimize its manufacturing process.

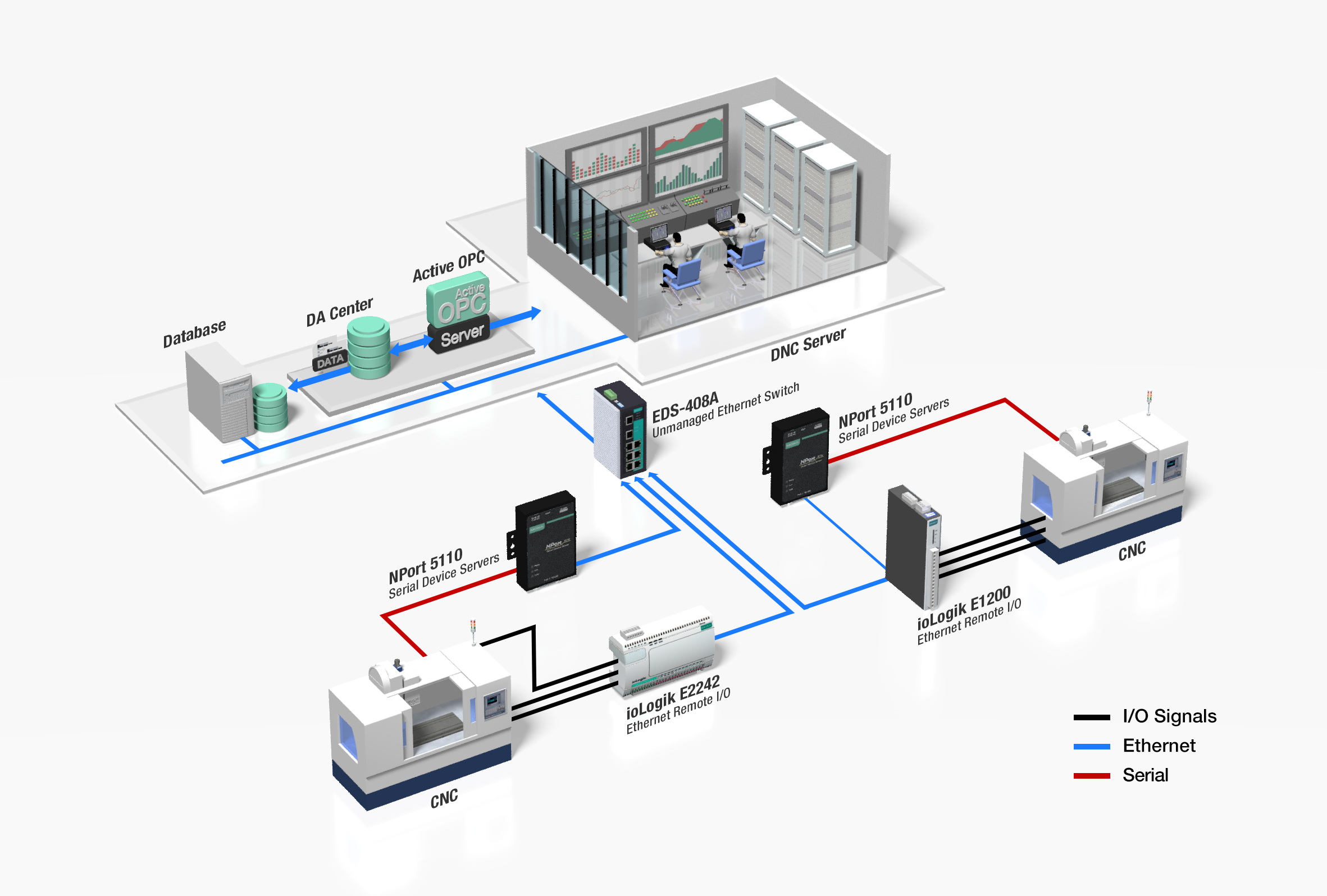

This computer integrated solution provider used Moxa’s NPort 5110 serial device servers to connect each CNC machine to the factory’s Ethernet backbone formed by Moxa’s EDS-408A unmanaged Ethernet switches. In this way, technicians were no longer required to manually install new manufacturing programs onto each CNC machine. However, technicians still had to make regularly scheduled visual inspections to ensure that the CNC machines were working properly. Each CNC machine had three different colored indicator lights that technicians used to monitor the machine’s status and determine specific maintenance tasks. A red light indicated that the system was offline or shut down, a green light indicated that the machine was idling, and a yellow light indicated that the system was running normally. The company realized they could save time and money by remotely monitoring the condition statuses of all the CNC machines by connecting each CNC machine to Moxa’s ioLogik Ethernet remote I/O server, which would notify the direct numerical control (DNC) server whenever a CNC machine was idle or offline.

System Requirements

- Active event triggers for data acquisition

- Assist in improving machine utilization

- Accurate data to develop dynamic production plans

- Provide real-time data for the MES and ERP system

Moxa Solution

The factory in China was looking for a solution that could provide readily available monitoring information about all the CNC machines’ statuses to help eliminate unnecessary maintenance visits and focus resources on system bottlenecks. Thanks to the NPort 5110 serial device servers connecting each CNC machine to the factory’s Ethernet backbone formed by EDS-408A unmanaged Ethernet switches, technicians were no longer required to manually install new manufacturing programs onto each CNC machine. However, technicians still had to make regularly scheduled visual inspections to ensure that the CNC machines were working properly. Each CNC machine had three different colored indicator lights that technicians used to monitor the machine’s status and determine specific maintenance tasks. A red light indicated that the system was off line or shut down, a green light indicated that the machine was idling, and a yellow light indicated that the system was running. Factory managers realized they could save time and money by remotely monitoring the condition statuses of all the CNC machines by connecting each CNC machine to an ioLogik Ethernet remote I/O server, which would notify the direct numerical control (DNC) server whenever a CNC machine was idle or off line.

Why Moxa

- Robust product design provides reliable operation in harsh environments

- Reliable serial-to-Ethernet communication without packet loss for precise production control

- Proactive data acquisition for real-time asset monitoring

- Intelligent local alarm alerts personnel and data analysis to save maintenance effort

- Complete industrial Ethernet communication and remote monitoring solutions